www.read-tpt.com

www.read-tpt.com

M

ay

2012

123

A

rticle

Although there are a large number of rolls,

they are of low purchasing and maintenance

costs due to a lighter weight of rolls, so the

roll cost distributed into the cost is low.

The square/rectangular tube mills can be

made without roll change. There are many

more product specifications of square/

rectangular tubes (including the section area,

length, wall thickness) than those of the

round tubes, the specifications are more

frequently changed, which takes more time.

Then, the performance advantage for no

roll change is quite remarkable. Olimpia 80

Tube Mills Machinery and FD Machinery are

manufacturing this kind of no roll change

square and rectangular tube mills.

The AUTO-DNSA mill was developed by FD

Machinery in 2011 on the basis of DNSA

technology. AUTO-DNSA refers to the

DNSA mill with automatic roll change and

automatic adjustment. FD has signed the

first supply contract with a Taiwan large steel

tube company and the mill will be put into

operation in June 2012.

The basics of the AUTO-DNSA mill are from

DNSA, which is an upgrade on the manual

automation of the DNSA mill. Like the

DNSA mill, the AUTO-DNSA mill has higher

requirements on the equipment precision

and rigidity compared with normal mills.

The differences are that in DNSA mills, the

tables are used to adjust the rolls manually

and the roll changes are done mechanically.

For the AUTO-DNSA mill, the automatic roll

change is done via programs for automatic

adjustment. The roll change (including

adjustment) takes less than an hour. When the equipment is

running, the operator can adjust the equipment any time without any

need of switch. The characteristics of the digitalisation, automation

and humanisation of AUTO-DNSA mill seem to make us see future

tube welding plants, where people in white shirts sit in the control

rooms at constant temperature far away from the noise, sending

out various production commands to each production line. Only

the suppliers are on the field to unload the steel coils continuously

to the specified locations, and the buyers are busy picking up their

steel tubes. One or two operators are responsible for changing the

blades, saw bits, induction coils and impeders or deal with some

minor troubles for all the mills. It does not cost much to have all this

achieved. The AUTO-DNSA mill will become the perfect ERW mill in

the world, if it can be turned to a reality.

FD Machinery Co Ltd

– China

Fax: +86 411 83192716

Email:

fd@fdmachinery.comWebsite:

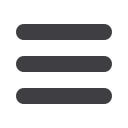

www.fdmachinery.comRapid roll change mill with base plate change by FD Machinery

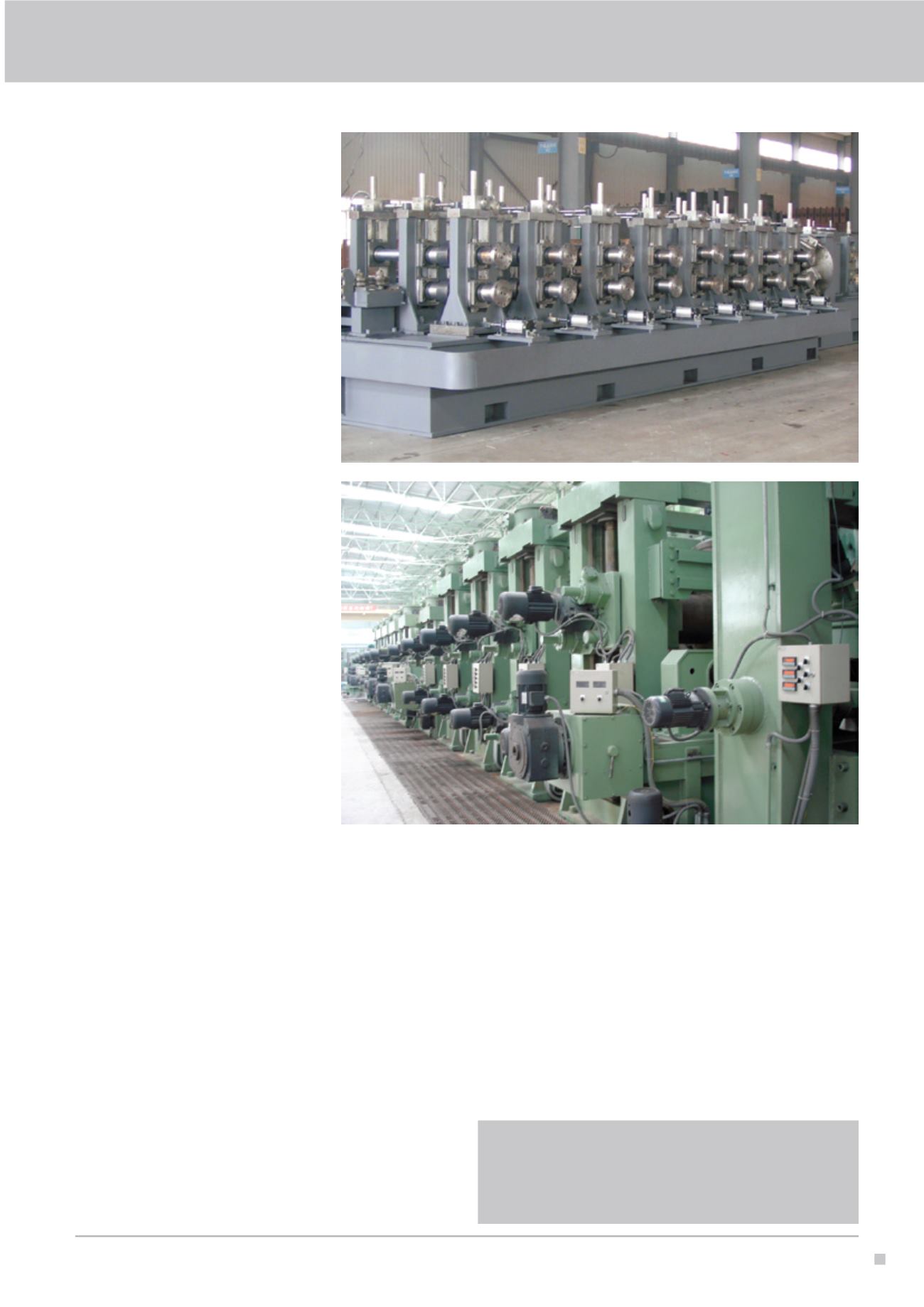

CFS mill of Ø200×200 Ø500×500mm by FD Machinery