16

MODERN QUARRYING

July - August 2015

AROUND THE

INDUSTRY

Coad explains that Afrimat prioritises ongo-

ing training to raise performance and productivity

standards.“We offer internal courses and use exter-

nal sources to facilitate continuous development.”

The group has a focused training division in

this regard, and in line with succession planning,

candidates are identified and receive personal

mentorship in furthering their formal education

and operational knowledge. Focus is on the areas

of mechanical and civil engineering as well as man-

agement, where previously disadvantaged candi-

dates have been appointed as trainee/assistant

managers as part of two-to-three-year develop-

ment programmes.

At the time of

MQ

’s visit, the plant was in the

process of a screen change, so all was quiet on our

walkabout. The primary plant consists of a 30/42

jaw crusher, two secondary cone crushers and one

Barmac shaper. As the plant is quite old, there have

been some upgrades with more planned in the

future. The latest acquisition is a Sandvik CS430

deep throat crusher which Coad is very happy with.

“It is robust, and with its constant intake opening,

is ideal for a high-capacity secondary crushing

operation.”

Coad says production on a monthly basis aver-

ages out to about 30 000 t/month and between

360 000 to 400 000 t/year.

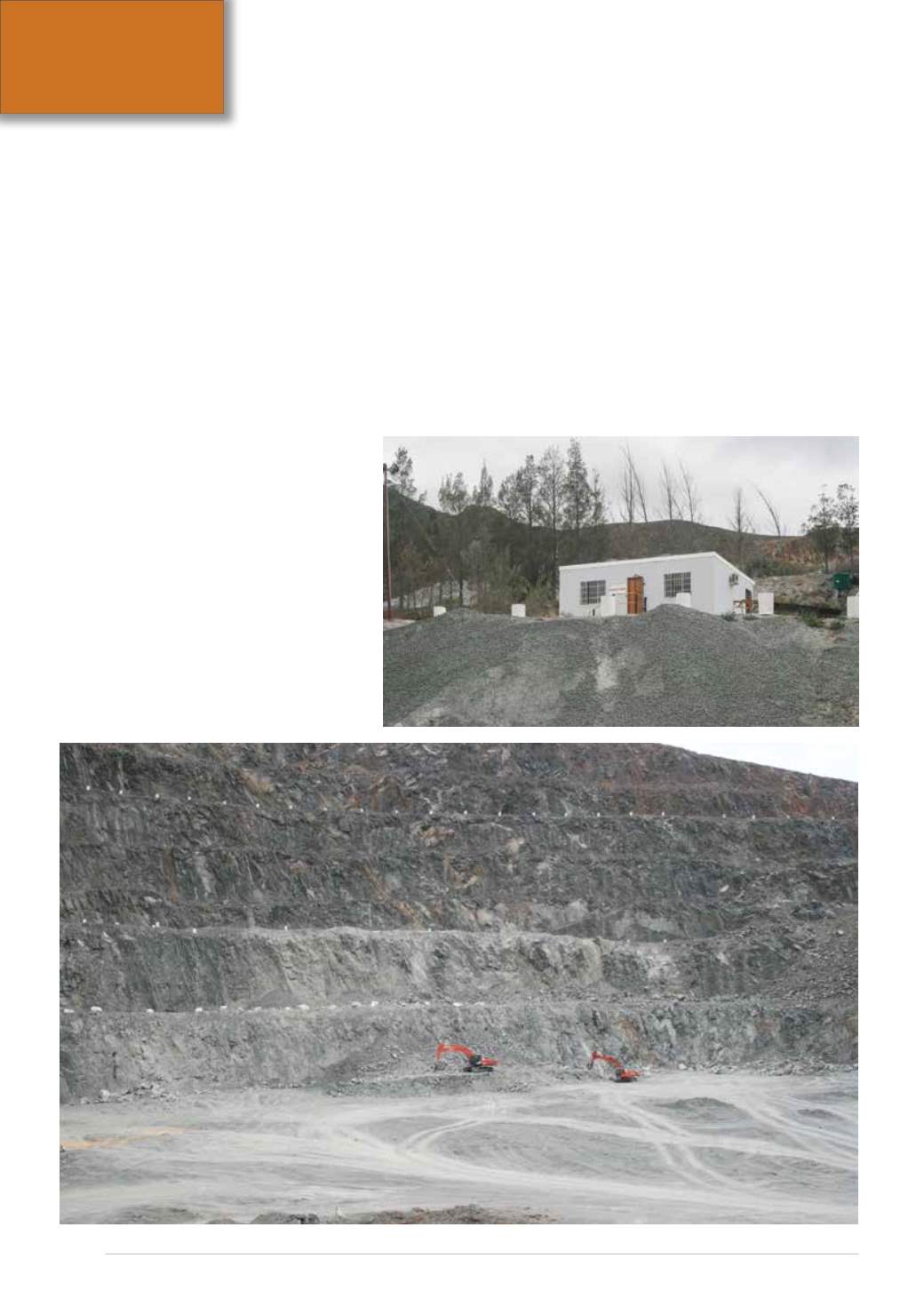

The mine is carrying out the pre-split lines on the benches

with future development being on the floor.

Ikaya Lethu – Our Home:

The new canteen was

named by the staff.

AT THE

QUARRY FACE

WITH

BREWELSKLOOF