UPM Annual Report 2016

UPM Annual Report 2016

44

45

In brief

Strategy

Businesses

Governance

Accounts

Stakeholders

CONTENTS

PROACTIVE OBSERVATION PREVENTS

ACCIDENTS

UPM’s new global reporting tool, One Safety was

successfully implemented at most UPM sites in 2016.

The aim is to have a common, UPM way of managing

safety and environment-related operations, and to

increase our commitment to safety and the environment.

According to studies, proactive observation is the best

way to prevent and reduce accidents. With the new global

way of working, UPM wants to encourage employees to

pay attention to their working environment, record potential

deficiencies and report incidents through the system.

The main features of the tool are the recording of observa

-

tions, near-miss situations and accidents, managing investi-

gations and corrective actions for incidents, preparing risk

assessments and reliable reporting. Proactive observation

is also promoted during regular safety walks.

External contractors working at UPM premises can also

record their observations to the system. With the tool,

UPM is also able to report and following-up the contractor

TRIF. The system also includes risk assessments related

to work permits and various tasks. Thanks to One Safety,

there has also been an increase in observations related

toenvironmental risks.

Read more:

www.upm.com/responsibilityUPM’s safety journey continues

UPM’s management system enforced by the “Step Change in Safety 2012-2014”

initiative also forms a solid foundation for future years. It means a systematic

approach, by means of audits and reporting, as well as a preventive and

engaging safety culture. The positive trend continued with the annual employee

engagement survey (EES): the Occupational Health and Safety score increased

1 percentage point compared to the previous year’s result.

All 13 UPM safety standards were updated in 2016. These standards describe

the minimum requirements that apply to all UPMpersonnel as well as contrac

tors working at UPMpremises or under UPM supervision.

UPM safety audits were conducted in production units within all business

areas. The purpose of these audits is to evaluate unit operations against agreed

OHS criteria (UPM safety standards, guidelines and legislation). Based on audit

results, most of the units have been able to further improve safety compared to

the results of previous audits.

One Safety – a global UPM safety tool

Regardless of severity, UPM employees and contractors are encouraged to

report all near misses and to make safety and environment observations.

In 2016, UPM introduced a global reporting tool, One Safety, for all UPMers

and contractors. The reporting tool covers environment, health and safety,

product and process safety as well as security. (Read more on the right).

Quarterly health themes

To support the wellbeing of its personnel, UPM is working in close co-

operation with employees and external occupational health organisations.

All UPM employees in Finland and Germany are represented by joint

employer–worker health and safety committees as defined in local legislation.

The aim of these location-based committees is to monitor and advise on

occupational health and safety issues and programmes.

In 2016, UPM continued with its quarterly health themes. The aim is to

support the continuous improvement of employees’ health, quality of life

and ability to perform. In 2016, themes related to good sleep, weight and

nutrition, and intoxicants (e.g. alcohol and tobacco). Additionally, free-time

accidents prevention, such as safe work practices at home and safe winter

or summer sports were covered.

Several health and wellbeing initiatives were launched at various UPM

sites and businesses globally with positive results. Thanks to a campaign

at the plywood mills in Finland, free-time accidents were halved.

Health and wellbeing coaching, which started in 2014, continued at different

businesses and sites in Finland.

To improve wellbeing at work, UPM is monitoring employees using several

metrics on a yearly basis. These indicators include the annual employee

engagement survey (EES), safety and absence indicators and occupational

health checks aligned with national legal requirements.

There is no high incidence or high risk of disease among UPM employees

related to their occupation. UPM analyses and manages the opportunities and

threats related to healthy working environments. In almost all of the

production sites, there can be a risk of disease related to employees’ occupation,

even when adequate protection is in use. Employees can be exposed to noise

causing auditory trauma or dust and chemicals causing occupational dermatitis

or asthma. To minimise health hazards UPMhas standardised processes,

for example for risk assessment, personal protective equipment and chemical

management. In addition, occupational health workplace surveys are

conducted to assess the working environment. The majority of UPM’s

employees work in areas with no or only minimal risk of HIV/AIDS, malaria or

tuberculosis. Instructions and support are available for employees travelling

to critical areas.

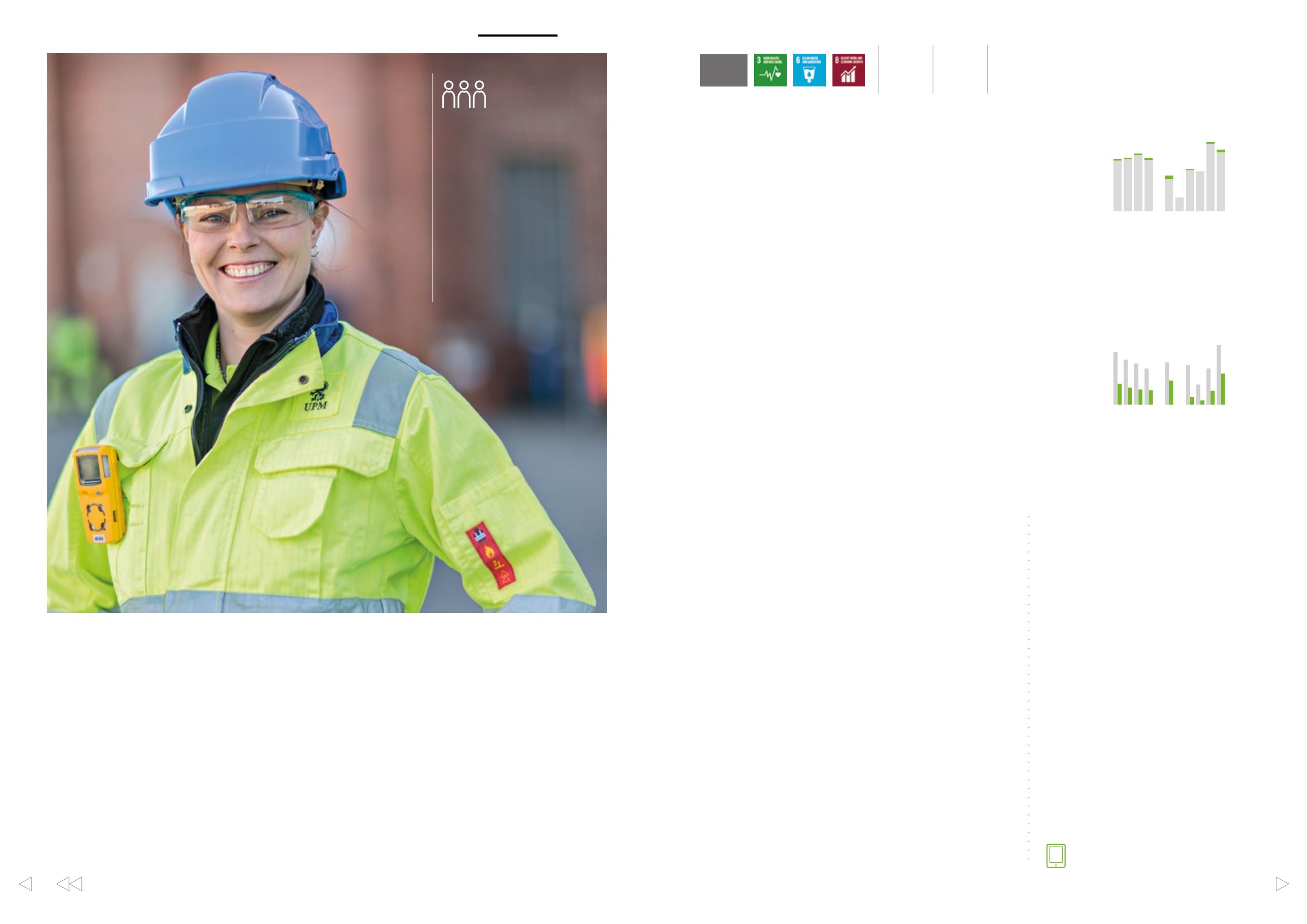

In 2016, UPM’s lost-time accident frequency (LTAF, the number of lost-

time work accidents per one million hours of work) was 3.7 (3.9). The TRIF

(total recordable injury frequency) improved, standing at 9.3 (10.6). The

TRIF includes LTA cases as well as modified duty cases and accidents

requiring medical treatment. The safety of the external workforce improved

as well. UPM’s contractors had 76 lost-time accidents (92 in 2015). The

figures show a positive development in terms of safety at UPM.

Unfortunately, there were two fatal accidents in 2016: one involving a

UPM employee at a Finnish paper mill and another involving a contractor

in UPM operations in Uruguay during forestry work. Thorough root cause

analyses have been conducted and key learnings have been shared to avoid

any future severe accidents, with a view to our continuous target of zero

accidents.

Good safety performance is recognised with company-wide safety awards.

The 2016 UPM Safety Award for the best improver was given to UPMFray

Bentos pulp mill in Uruguay.

In April, UPM celebrated the company’s fourth Safety Week in connection

with the World Day for Safety and Health at Work organised by the

International Labour Organization (ILO).

Safety is an essential part of UPM’s

activities and business management system.

Equal safety requirements are applied to all

employees, visitors and contractors working

at UPM’s premises.

Driving continuous

improvement

in safety

Lost time accident

frequency for employees

and contractors

3.7 6.2

TARGETS

2030

13 14 15 16

UPM Energy

UPM Raflatac

UPM Specialty Papers

UPM Paper ENA

UPM Plywood

UPM Biorefining

5

4

3

2

1

0

Absenteeism due to sickness and

accidents at work, UPM workforce

% absence hours/

theoretical working time

■

Accidents at work

■

Sick leave

13 14 15 16

UPM Energy

UPM Raflatac

UPM Specialty Papers

UPM Paper ENA

UPM Plywood

UPM Biorefining

20

15

10

5

0

Total recordable injury frequency

and lost-time accident frequency,

UPM workforce

■

Total recordable injury frequency*

)

■

Lost-time accident frequency**

)

*

)

Total injuries/one million hours worked

**

)

Number of lost-time accidents/

one million hours worked

Coverage of One Safety tool

75%

of UPM employees

In 2016, a total of

44,000

safety related near-miss and safety

observation reports were recorded.

38,400

safety walks and discussions