CAPITAL EQUIPMENT NEWS

APRIL 2015

6

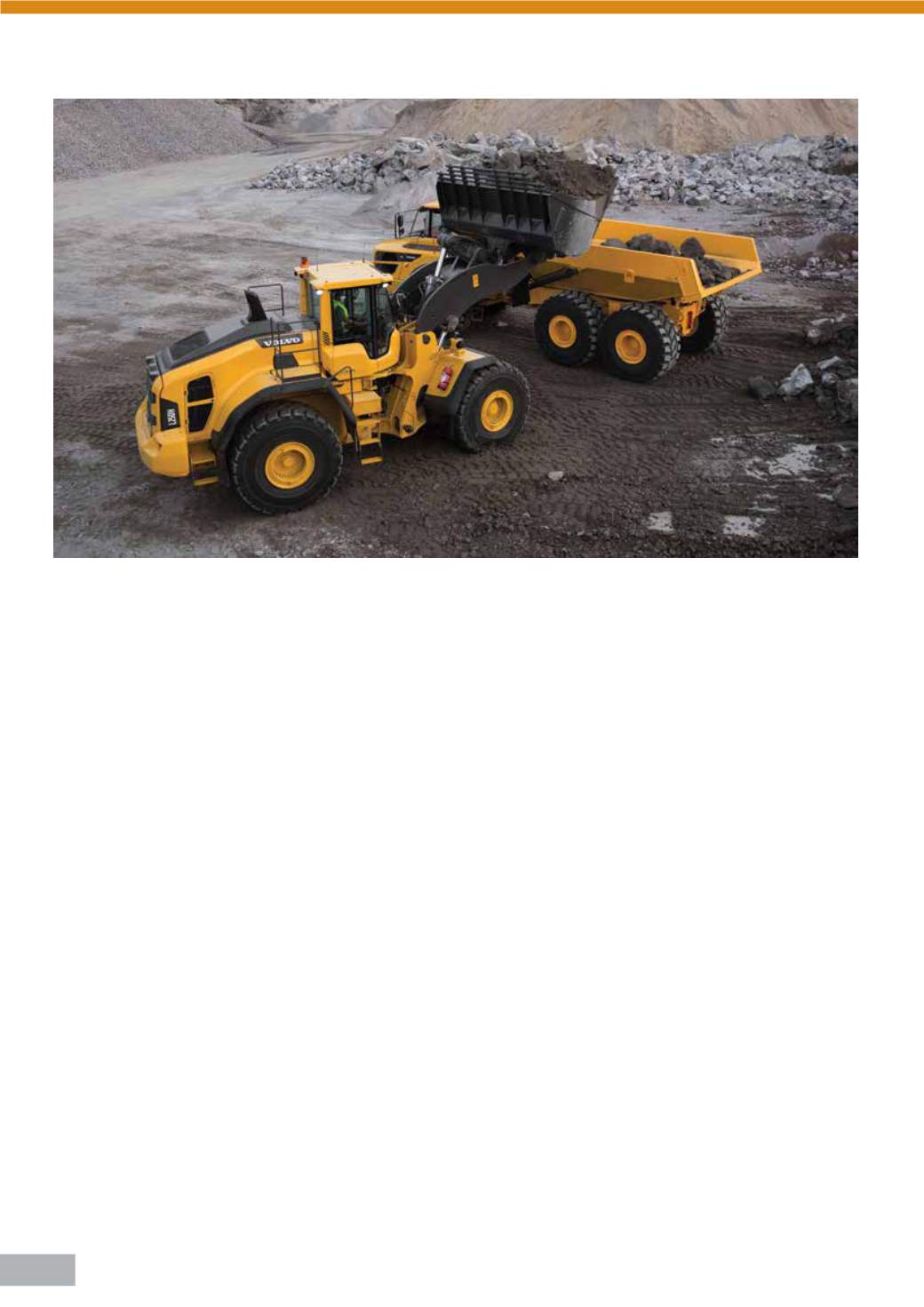

T

he Volvo L250H wheel loader is a

high production machine designed

to deliver excellent productivity and

profitability in applications including quar-

ry, mining and heavy infrastructure. Opera-

tors will experience short cycle times, high

breakout force and excellent controllability

with this heavy-duty machine with an oper-

ating weight of 39 940 kg.

Featuring advanced technology and built on

decades of experience, the L250H’s power-

ful Volvo D13J engine producing 291 kW,

provides high performance and low fuel

consumption. During the fully automated

regeneration process, particulate matter

collected in the DPF is burnt off without in-

terrupting performance or productivity for

effortlessly clean operation.

Fuel efficiency is enhanced by Volvo’s Opti-

Shift technology, which combines the com-

pany’s patented Reverse By Braking (RBB)

technology and a torque converter with lock-

up to eliminate power losses and reduce

fuel consumption by up to 18%. Automatic

Power Shift (APS) and Fully Automatic Power

Shift (FAPS) further ensure minimal fuel con-

sumption and fast cycle times, shifting the

machine gears in line with engine and trav-

el speed for optimal operation. Meanwhile

Volvo’s eco pedal encourages the operator

to ease off the throttle, therefore lowering

fuel consumption, by applying a mechanical

push-back force when the throttle is used

excessively and the engine rpm is about

to exceed the economic operating range.

Intelligent load-sensing hydraulics supply

power to the hydraulic functions only when

required for smooth, fuel-efficient operation,

as well as excellent control over the load and

attachment.

The Volvo L250H is not only one of the most

efficient heavy-duty wheel loaders on the

market but also one of the most productive.

Volvo’s proven Z-bar linkage provides high

breakout force of 336 kN for strong, power-

ful digging in hard materials and facilitates

quick load cycles for increased productivity

even in demanding applications. The op-

tional Boom Suspension System (BSS) fur-

ther boosts productivity, by up to 20%, by

absorbing shock and reducing the bouncing

and bucket spillage that occurs when oper-

ating on rough ground. This enables faster

and more comfortable work cycles and in-

creases machine life. As for the optimal-

ly-shaped bucket, it has been designed to

incorporate a spill guard, side cutters and

wear plate for faster and more efficient

bucket fill and longer service life.

A specially designed 9.0 cubic yard rehan-

dling bucket gives faster and more efficient

bucket fill – and up to 10 percent better fuel

efficiency.

With a variety of product options, Volvo cus-

tomers can adapt their machine to access

more applications, such as rock and waste

handling. Attachments are purpose-built to

work in harmony with the L250H. Functions

and properties are ideally matched to pa-

rameters, such as link-arm geometry and

breakout, rim pull and lifting force for maxi-

mum productivity.

b

VOLVO L250H WHEEL LOADER

high productivity workhorse

“The Volvo L250H is not only

one of the most efficient

heavy-duty wheel loaders on

the market but also one of the

most productive.”