CONTROL SYSTEMS + AUTOMATION

• Avoiding excessive or cumbersome management plans

• Modular approach to functional design specification (URS)

• Recording the verification process

• Recording the validation process using the URS

Other subsidiary topics for discussion are:

• Detecting and final control Elements

o The rise of programmable ormore accurately 'parameterable'

(if that’s a word) elements presents its own set of challenges

o Traditional detecting and final elements had a dedicated

single function. It did exactly ‘what it said on the tin’

o These elements continue to develop with self-teach func-

tions, floating muting, profile for safe minimum speed, etc.

o One must take care that with all the available flexibility,

that the required safety function is being executed

• Areas of most frequent sub-standard design

Figure 2: Areas of most frequent sub-standard design.

These figures are not based on recorded statistics, but from observa-

tion of many projects. The high error rate for final control elements,

is mainly due to non-safe rated components in a safety loop without

sufficient diagnostics, redundancy or insufficient Mean Time To

dangerous Failure (MTTFd).

Modular User Requirement Specification

On a large or more complex project, where there aremultiple suppliers

of major sections of plant, in addition these suppliers may be fromdif-

ferent countries with varying statuary regulation. This places greater

emphasis the URS and the Safety Management Plan. Hypothetically,

we are considering a project which covers many hundreds of square

metres, several thousand I/O (regular control) and different complexes

of machinery. It is a production process using a variety of complex

machinery. We are discussing the delivery of the safety system for

this. A modular approach to requirement specification of safety

functions and then building these modules into safety loops, creates

a clear and unambiguous statement. In broad terms, typical safety

loops can be grouped into the following (the list is not definitive):

• E-Stop

o Zoning

o Class of stop function (break for free run)

• Access Control

o Physical restraint with interlock or guard locking

• Presence sensing

• Muting or Bypass

o Safe speed

o Hold to run / Jog

• Process interlock

o Hazard materials

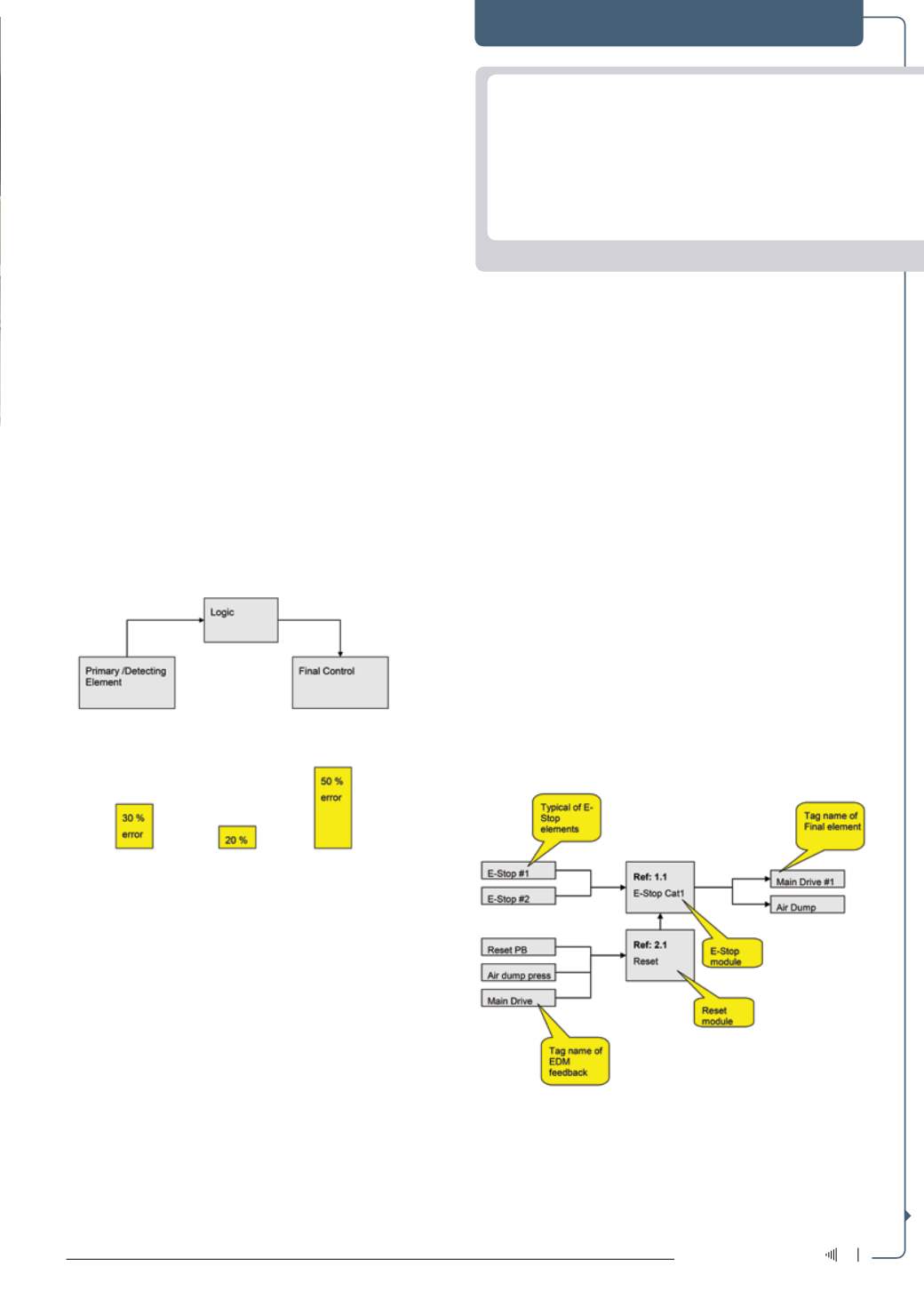

Rather than specifying the detail function of each complete safety

loop, of which there may be several hundred in a large complex

project, one chooses the modules that make up the loop. Some of

the benefits to this type of development are:

• Avoids repetition of stating the same function in each safety loop

• Transparent to the hardware or software platform being used

• Diagrammatic format tends towards a clear, and unambiguous

definition

• A revision of a module does not require it to be exhaustively

revised in every loop. Change it once at the module definition

and it is referenced to wherever it is called

Figure 3: Example E-Stop loop.

In the example the module Ref 1.1 E-Stop and the module Ref: 2.1

Reset are specified for this particular safety loop. The Ref: 1.1 E-Stop

may be re used again and again in other E-Stop loops. All that changes

are the tag names of the input elements and output elements.

Abbreviations/Acronyms

CRC

– Cyclic Redundancy Check

EDM – External Device Monitoring

I/O

– Input/Output

IEC

– International Electrotechnical Commission

ISO – International Standards Organisation

MTTFd – Mean Time To dangerous Failure

PLC

– Programmable Logic Controller

PLr

– Performance Level

SIL

– Safety Integration Level

SRCS – Safety-Related Control Systems

URS

– User Requirement Specification

5

February ‘16

Electricity+Control