PRODUCT News

June 2015

MODERN MINING

55

Having delivered an impressive perfor-

mance in several overseas applications,

Sandvik CR810 hybrid roll crushers are

now starting to prove themselves in the

African mining environment. A recent two-

year study conducted at Genet Mineral

Processing’s Onverdacht colliery near

Belfast in Mpumalanga has demonstrated

that even extremely hard South African

coal can be crushed in a primary or sec-

ondary application at a cost as low as 55

cents per ton.

Sandvik CR810 hybrid roll crushers

store kinetic energy in the mounted fly-

wheels (belt drive models) and the fast

running fly wheels (direct drive models).

A flywheel located on each roller delivers

a crushing power up to four times that of

a crusher without any flywheel, increasing

the capacity and improving the maximum

material hardness by nearly 65 %. This

enables the machine to crush large lumps

and maintain a stable crushing process

even during peak conditions.

“The Sandvik CR810 has proved ideal for

primary and secondary crushing of materi-

als that are soft to medium-hard, as well as

wet and sticky,”says Sandvik Mining’s Colin

Jones, Crushing and Screening Division,

Region Africa. “Its compact design less-

ens the required installation footprint

and it utilises roller teeth with a large gap,

allowing it to produce high quality output

products with very low fines.

“The teeth are installed in a line, instead

of the conventional scroll pattern, at 120

degrees, which allows greater penetration

into the crusher. The teeth are also inter-

laced for bending and shearing, with a

lower tooth that delivers compaction. The

end result is a cubical product. Scrappers

are fitted to keep the teeth clean and there

is no other crusher in the world that has

this feature.”

Depending on the application and

model, Sandvik crushers of this type can

achieve capacities in a range of 100 up to

11 500 metric tons per hour (t/h) and can

be used in primary, secondary and tertiary

crushing applications.

“Sandvik hybrid crushing technology

was first tested on limestone and sand-

stone in Europe and continues to deliver

exceptional performance in these sectors

today,” Jones says. “Two years ago, when

sample analysis of the coal being mined at

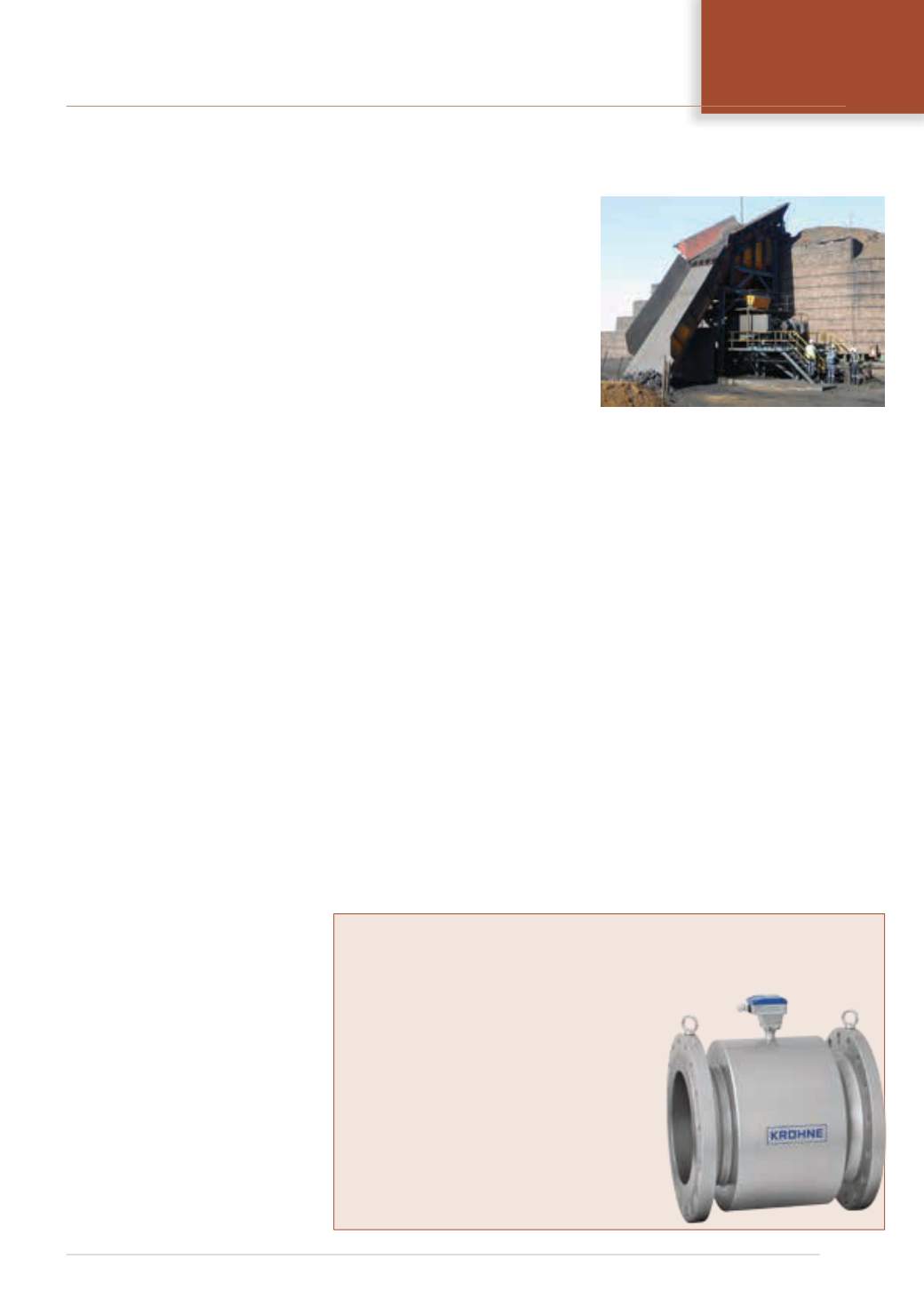

Flowmeter is a ‘plug and play’ solution

With no cables or other parts protruding past the flanges, compact dimensions and a low

weight, the UFM 3030 flowmeter from KROHNE is very easy to handle.

The outer casing of the UFM 3030 is an all metal con-

struction and there is therefore little risk of damage to

the flowmeter during the installation process.

The flowmeter is delivered ready to measure.

Once mechanically and electrically connected, the

unit does not require any specific handling such as

fitting sensitive transducer parts or making specific

cable connections. In case of a remote installation, a

cable with pre-fitted connectors is provided. In this

way the signal connections are easily made without

the need for special handling. The cable length can

be selected from 5 up to 100 m.

KROHNE, tel (+27 11) 314-1391

Hybrid roll crusher proves itself at SA colliery

Onverdacht colliery indicated a hardness

of 70 MPa, with the surrounding sand-

stone at 150 MPa, we recommended this

machine to management and began a test

programme on the mine.”

The Onverdacht roll crushing plant has

a capacity of 250 t/h with a static grizzly

on the feed bin and the bars set 400 mm

apart. Considering that the third dimen-

sion was approximately 500 mm, the

machine selected was the Hybrid CR810/

08–10. This model incorporates rolls

800 mm in diameter and 1 000 mm long,

and features rapid tramp metal release,

self-cleaning of wet and sticky material

and three dimensional crushing using a

kinetic energy input.

The machine was put into service in

January 2013 with a gap setting of 100 mm

where 90 % of the feed material passed.

Shortly after the plant was commis-

sioned, it was decided to reduce this gap

to -75 mm to help the secondary crushers

produce a final product of P100 < 40 mm.

Roll speed is the same as material flow

speed, so there is no retention time.

In terms of maintenance and repair, in

August 2013 it was noted that the fixed

roll bearing was becoming hot. The bear-

ing was repaired and the crusher was

back in operation just four days later.

Subsequently, in October 2013, a loose

bolt was detected and the plant was shut

down for 12 hours to tighten all the other

bolts in the installation. Over the two-year

trial period, plant availability was 98,6 %.

“During the plant’s operation, power

consumptionwas measured periodically for

both motors at 108 kW,” Jones says. “With a

throughput of 250 t/h and using 60 cents

per kWh, we determined that the consump-

tion was 0,432 kWh, or 26 cents per ton.

“By October 2014 the plant had

produced about 1,5 Mt and the mine pur-

chased a complete set of wear segments

at a cost of R300 000. Based on the cost of

the entire spare and wear parts and power

consumption, it was possible to accurately

calculate an operating expenditure (OPEX)

figure of 55 cents per ton.”

Rory Power, Group Maintenance

Engineer at Genet Mineral Processing, says

the Sandvik hybrid crusher has proved to

generate fewer fines than previously expe-

rienced with other crusher configurations.

A second Sandvik CR810 hybrid roll

crusher is in operation in South Africa in a

chrome application and three are at work

in the DRC crushing copper ores and gold

oxides.

Sandvik Mining, tel (+27 11) 929-5400,

website:

www.mc.sandvik.com/zaThe Sandvik CR810/ 08–10 hybrid roll crusher installed at

Onverdacht colliery near Belfast in Mpumalanga.