22

Wire & Cable ASIA – January/February 2017

www.read-wca.comIndustry

news

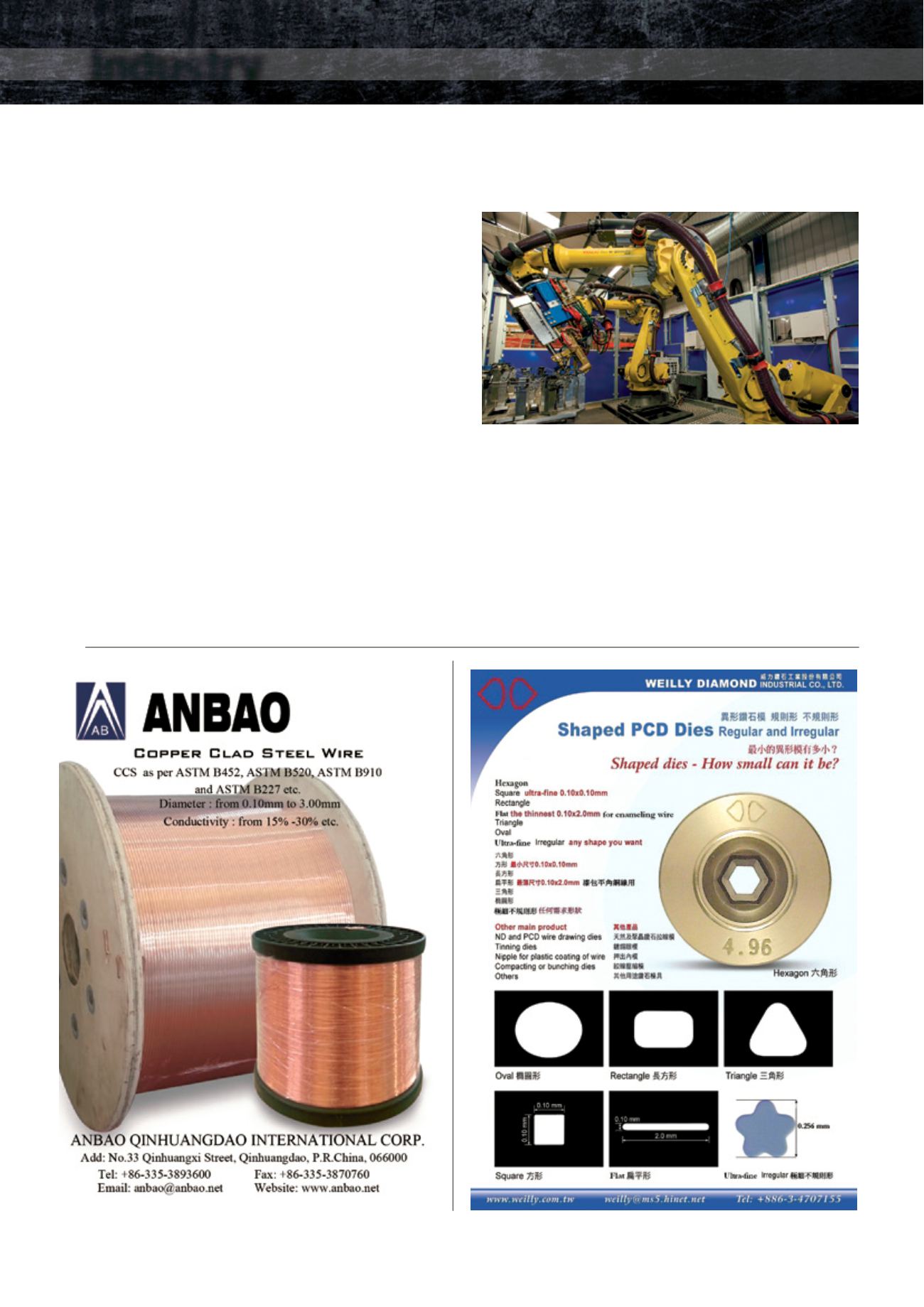

WILLIAM Hughes, specialist manufacturer of springs and

bent wire components for the global automotive and

aerospace industries, has invested more than £250,000 in a

high technology twin robot welding cell.

The new welding cell was supplied by Bauromat with Fanuc

robots, all installed at William Hughes’ new UK headquarters

in Stalbridge, Dorset. The unit features advanced weld

monitoring and recording ensuring that the highest standards

of quality and consistency are maintained for its customers.

“We have been very successful in winning significant new

business from our automotive customers and this has meant

that we needed to increase our production capacity for our

welded seat frame assemblies,” said Emma Burgon,

engineering director.

The welding cell is in operation 24 hours a day during the

working week and is currently being used for the bulk

manufacture of seat frame backs for an SUV. This particular

assembly has 56 welds and uses 25 wires.

As well as the improved quality and consistency of the

finished product provided by the twin robot cell, the welding

process is much quicker, enabling parts to be produced in

just 1 minute 40 seconds compared with 3 minutes 45

seconds previously. Furthermore, to ensure throughput speed

is maximised, the weld jigs are all designed by William

Hughes engineers using the latest CAD software and

manufactured using CNC milling machines.

This recent investment in the latest manufacturing technology

continues the programme of continued growth which includes

the opening in October 2014 of a new 87,000ft

2

factory at its

UK base in Stalbridge.

William Hughes Ltd – UK

Website

:

www.wmhughes.co.uk£250,000 investment in latest welding technology

❍

The twin robot welding cell