4

Mechanical Technology — March 2015

⎪

On the cover

⎪

W

eir Minerals Africa not only

offers the most innovative

pump products, but also

gives existing customers

the opportunity to update their older

pumps in order to take advantage of the

latest developments. “While we make

ongoing improvements in terms of using

the latest construction materials and im-

proving the performance of our products,

we continue to service and support the

large base of our tried-and-tested older

technology products throughout Africa,”

Fawcett says.

While the Warman

®

AH

®

pumps are

well-known on the African continent, he

says that Weir Minerals Africa is turning

its attention to helping its customers im-

prove their processes and optimise their

plants. “The question now is how can

we make improvements within a defined

operational environment, where each

plant has an installed base of pumps

and equipment with fixed dimensional

tolerances.”

Constant support and a rapid response

time are more important than ever before.

“Within the context of the currently con-

strained economic environment, few min-

ing operations have the capex available

to replace an entire fleet of equipment.

Typically, return on investment periods

used to be three to five years, but that

horizon is now a maximum of 12 months.

Therefore, products have to be able to

demonstrate the savings required within

that period in order to add value for our

customers. Unfortunately in today’s mar-

ket some of these decisions at customer

level are made only on one-dimensional

initial cost, with the long term reliabil-

ity and impact on process performance

and reliability not always considered,”

Fawcett says.

“We have a major focus on increasing

the durability and lifespan of compo-

Weir Minerals Africa is turning its attention to helping its customers improve

their processes and optimise their plants. “The question now is how can we

make improvements within a defined operational environment, where each

plant has an installed base of pumps and equipment with fixed dimensional

tolerances,” says Rob Fawcett, sales, marketing and engineering director:

Weir Minerals Africa and the Middle East.

Rob Fawcett, sales, marketing and engineer-

ing director at Weir Minerals Africa and the

Middle East.

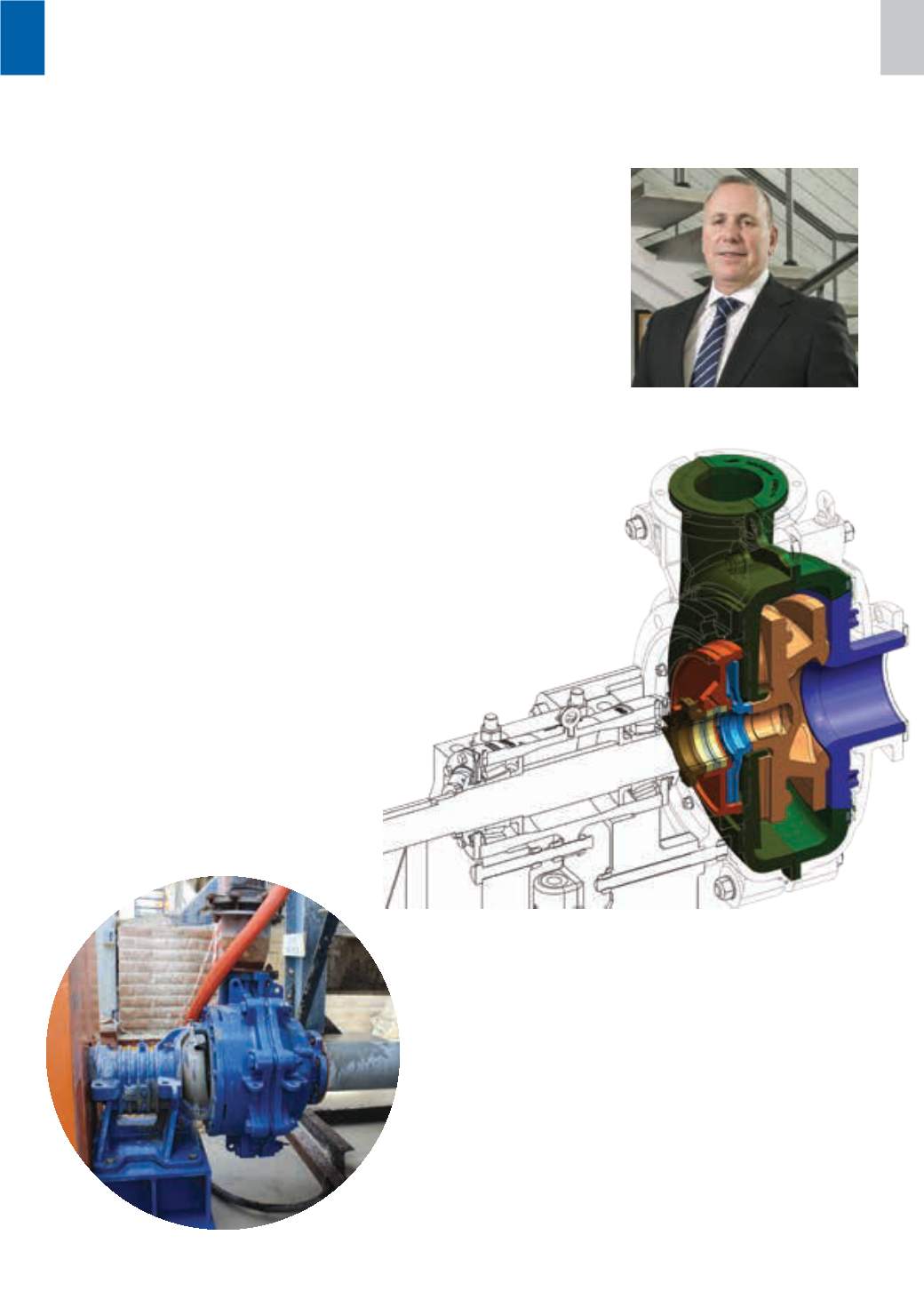

The new Warman WBH

®

slurry pump installed in a

sand and aggregate application.

A sectional view of a Warman AH

®

pump

showing the improved technol-

ogy rubber liner, Hi Seal

expeller and

wear reduction

technology.

Innovative pump products for improved

nents, which translates into less down-

time and reduced spares usage. This has

proven successful in the marketplace,

and forms part of our standard of-

fering for all new pumps. Over the

last three to four years, through

our retrofit programme, these

improvements have been and are

being made available to the exist-

ing installed base,” Fawcett says.

These improvements range

from the hydraulic design within the

pump unit itself to complete pump

range redesign. As a slurry pump differs

from its clear water counterpart, there is

a need to strike a balance between ef-

ficiency and excellent wear performance.

We have been able to demonstrate a

dual benefit in terms of energy savings

as well as improved performance,”

Fawcett adds.

This philosophy of combining energy

savings with improved performance is

at the heart of the Weir Minerals Africa

market strategy, and was applied when

reviewing the entire mill circuit. It

resulted in solutions being developed

that combine Enduron

®

high-pressure

grinding mills with KHD technology,

Warman

®

slurry pumps, Linatex

®

rubber

products, Trio

®

comminution equipment,

Vulco

®

wear-resistant linings, Cavex

®