www.read-tpt.com

www.read-tpt.com

30

J

uly

2016

T E CHNOLOG Y

No.5, Jingke 7th Rd., Nantun Dist., Taichung City 408, Taiwan

TEL: 886-4-23553111 E-mail:

eyan@eyan.comFAX: 886-4-23552111

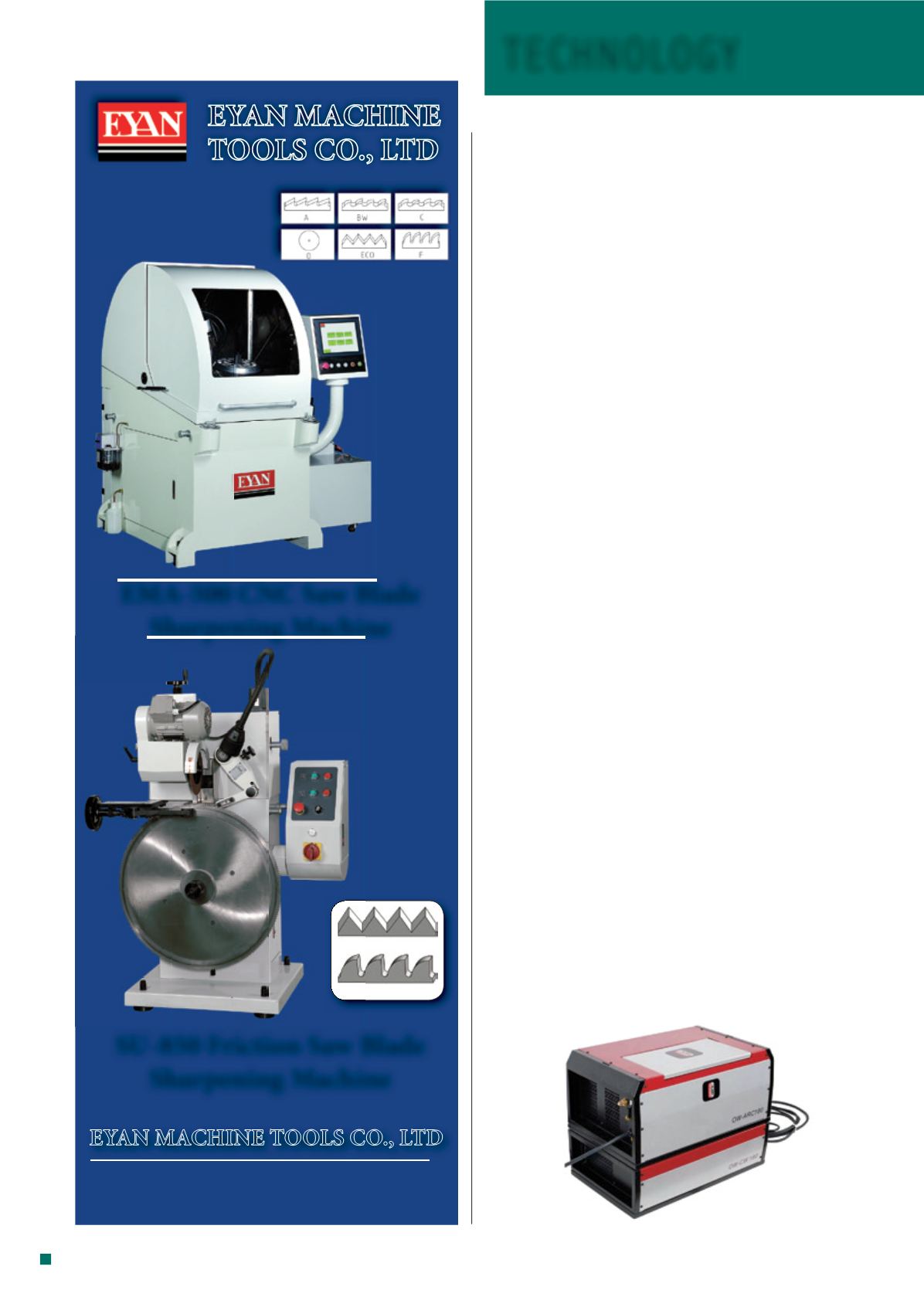

http://www.eyan.comEMA-500 CNC Saw Blade

Sharpening Machine

SU-850 Friction Saw Blade

Sharpening Machine

EYAN MACHINE

TOOLS CO., LTD

ECO

F

EYAN MACHINE TOOLS CO., LTD

30 years of tooling

BEND Tooling Inc, USA, has supplied companies around

the world with tube bending tooling since 1986, and is now

celebrating 30 years producing die sets, mandrels and wipers

for rotary-draw tube bending machines for most makes and

models.

Its designs are used by production tube bending operations

in the automotive, sports vehicle, HVAC and hydroforming

industries.

They are also used by speciality tube bending companies

because of their consistency in specification, which facilitates

frequent changes in set-up.

Bend Tooling states that tube bending companies can

benefit from consistent reliability, easier stocking and just-in-

time shipping of its inserted mandrels and wipers in place of

traditional solid-body ones.

The company also manufactures solid-body mandrels and

wipers for those tube bending jobs that require them. This

primarily includes bending under extreme high pressures

and bending non-round tube.

Bend Tooling, Inc

– USA

Fax: +1 616 454 9958

Email:

info@bendtooling.comWebsite:

www.bendtooling.comHigh performance

welding power supply

THE Otto Arc 180 power supply has been designed to

ensure high quality welds using both fusion and open wire

feeder heads, and over 20 levels of programming for detailed

accuracy.

The 10" colour screen along with features such as a USB

port, remote pendant, printer, fault detection and a water

cooling system are integrated as a complete package.

The PC controller offers easy programming, and provides

versatility to tackle demanding applications including food

and dairy manufacturing.

Otto Arc Systems, Inc

– USA

Website:

www.ottoarc.comOtto Arc’s 180 power supply