CONSTRUCTION WORLD

SEPTEMBER

2017

20

Special attention was required to an existing sub-surface canal

running south to north which intersects the eastern portion of the site

with both the lateral support and piled foundation design modified to

accommodate and maintain the integrity of this structure.

“It is evident that from a geotechnical perspective the Cape

Town Foreshore is not the easiest area in which to operate. The

varying ground conditions with old rock-filled docks and piers

and the high-water table as described above present a significant

challenge,” says Franki’s Rod Schultz. “But our previous experience

on the neighbouring Harbour Bridge and Canal Quays projects gave

us a thorough understanding of the prevailing ground conditions in

the area and enabled us to quickly offer our client the most cost-

effective solution,” he says.

Schultz says that it took some years of on-and-off development

proposals by all, before AMDEC succeeded in producing a workable

solution by securing the land and obtaining the necessary partner-

ships to go ahead.

Due to the past successful working partnerships between Franki

and AMDEC, Franki was the preferred contractor for this challenging

geotechnical work. “We know Franki’s exceptional capabilities in

the Foreshore area, which requires a special understanding of its

complex geological conditions. We had no hesitation in awarding

Franki this contract and their performance certainly lived up to

expectations,” says AMDEC’s Project Manager Arnon van As.

Franki’s scope of works included the design

and installation of the lateral support and

foundation piling to this multi-storeyed, double-

basement project, the excavation and disposal

of some 65 000 m

3

of bulk earthworks, 508 lm

of lateral support and 271 no. foundation piles.

The soldier piles for the lateral support were

a combination of 400 mmØ Continuous Flight

Auger (CFA) piles and 325 mmØ Rotapiles

tied back with a single row of anchors and

gunite arches. The anchors had to be carefully

positioned and inclined sufficiently to not

intersect with the canal, which runs very close

to the site.

CFA piling is a fast and economical system

with no vibration and limited noise levels

associated with it. “This was particularly

advantageous on a site which is close to live

canals and railway lines, contains a labyrinth of

existing services and has neighbours who are

particularly sensitive to noise,” says Schultz.

The main feature of the Rotapile system

is its ability to penetrate boulders and

rock formations. Socketing into hard rock

COVER STORY

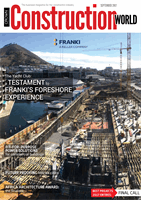

The Yacht Club, a multi-use development including commercial

and residential space, is destined to become one of Cape Town’s

most sought after destinations and is yet another prestigious

AMDEC/Franki Africa partnership.

The site is situated on the Malmesbury group deposition of

the Cape Peninsula, Cape Supergroup in the Foreshore area of the

harbour reclamation development of the 1920s and 1940s. The

shale bedrock is overlain by very stiff residual material followed by

marine deposits and fill comprising old harbour facilities, general

tipped rubble and dredged sands.

The ground water table was intersected at an average depth of

0,86 m with the bedrock falling from around -0,84 m in the west to

-2,9 m in the east (elevation levels in ASML).

Plain Sailing with Franki …

The Yacht Club, a testament to

FRANKI’S FORESHORE EXPERIENCE

AMDEC Property Development’s (AMDEC) The Yacht

Club development is a picturesque, nautically in-

spired design, located on the Cape Town Foreshore

in the Roggebaai Canal Tourism Precinct near to the

Cape Town International Convention Centre (CTICC)

and directly south of the new multi million Rand

cruise liner terminal.

Piling and bulk earthworks operations at peak

with upwards of five piling rigs, two excavators

and more than 200 tipper truck loads per day.