Inspection, testing & qual ity control

www.read-tpt.comM

arch

2015

95

SIDE LOADING FOR FAST TOOL

CHANGE AND NO LIFTING REQUIRED

• Infinitely adjustable

expansion & reduction

• High production

capability

• Up to Ø 152mm

• No tube clamping

required

• End form on or

near bends

• High quality build with

practical platforms

• Full 12 month warranty.

• Twin Head Machines

also available

Unit 24, Padgets Lane, South Moons Moat,

Redditch, Worcestershire B98 0RB, England.

T: +44 (0)1527 518520 E:

info@avamatic.co.ukW:

www.avamatic.co.ukGermany: Tel: 02150 2500

Netherlands/Belgium: Tel: (04756) 6888 USA: Tel: 708 272 7880

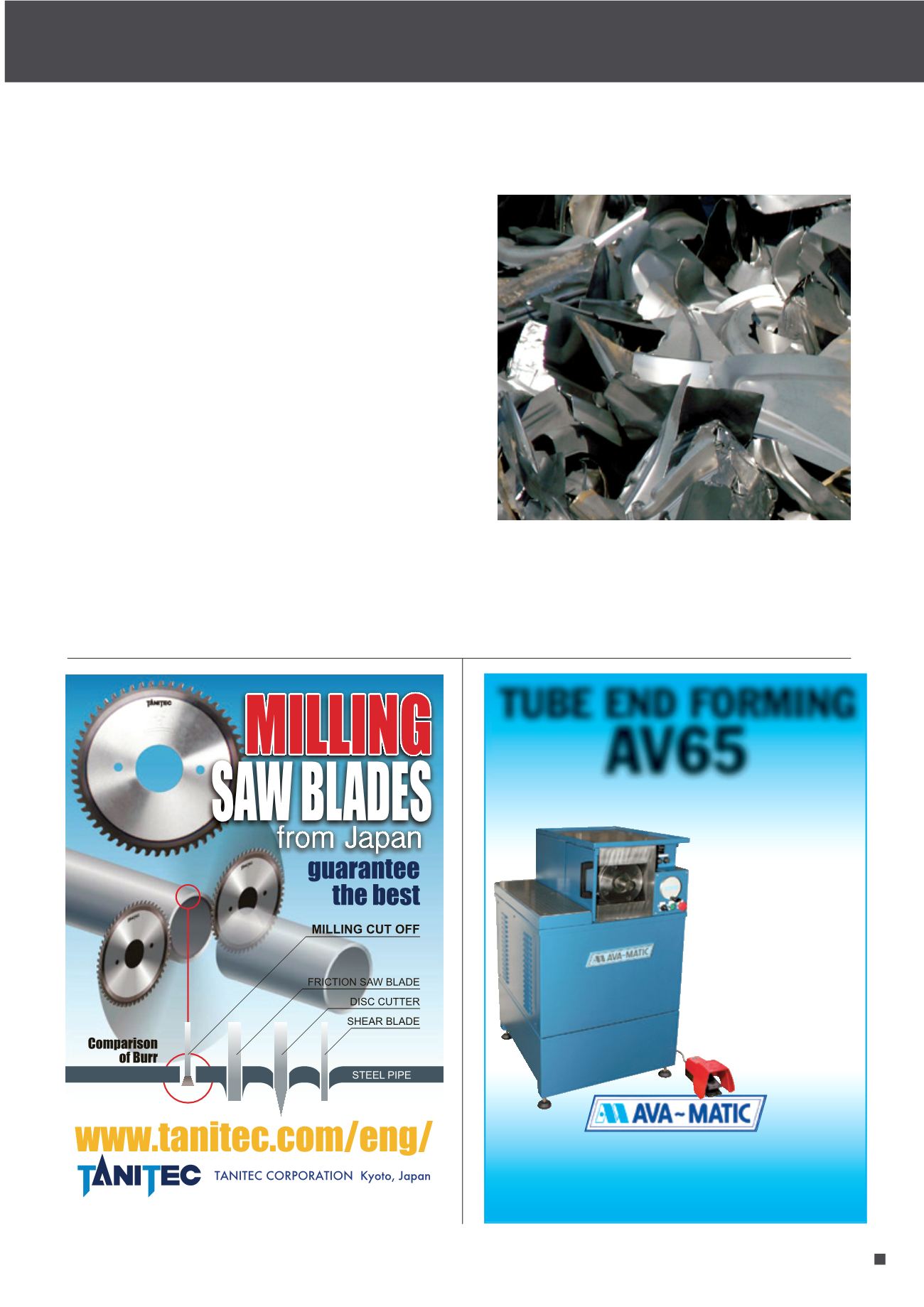

TUBE END FORMING

AV65

B-scan inspection system

SCRAP reduction is of particular

importance to the welded tube industry;

relatively small reductions in percentage

scrap can yield large savings. For

tube manufacturers, monitoring the

weld flash removal process on line

well before problems are revealed at

cut-off is an attractive scrap reduction

tool, particularly when post-weld heat

treatment imposes long cooling runs

before cut-off.

The InspecTech B-scan Inspection

System (IBIS) was first sold to the welded

tube industry more than 20 years ago.

The unit was conceived and engineered

around the ‘need to know’ the condition

of the inside flash removal process, and

the resulting scrap reduction potential.

As computing power has increased,

the performance and utility of IBIS have

improved. Displays, once delayed, have

moved to real-time, and the OD profile

of the tube has been included on the

screen in addition to the thickness scale.

InspecTech has announced new

software and firmware enhancements

that have made the IBIS

more user-friendly and

flexible. In addition, the

HMI (human-machine

interface) has been

updated and improved.

The test head of

the IBIS flash monitor

scans across the weld

zone and adjoining

parent metal covering

a band around 50mm

wide. The ultrasonic

system

makes

thousands of readings

during each sweep,

measuring both the

material

thickness

and the outer surface

profile.

Rather than a curved profile, IBIS

displays a set of Cartesian plots that

are calibrated directly in engineering

units (inches or millimetres), and which

may be used to define alarm limits

and display allowable tolerances. The

company states that this would not be

practicable in polar views.

InspecTech

– Canada

Email:

group@inspectech.caWebsite:

www.inspectech.ca