10

Electricity

+

Control

JULY 2017

A

t the forefront of successful designs lies

the correct specification of the mechani-

cal components used. This article concen-

trates on the key interface, the speed reducer

which couples a driving motor to a driven load.

Speed reducer functions

• Match motor top speed to load

• Match motor rotor inertia to load inertia

• Isolate drive from load environment

From this, it will become apparent that reducer se-

lection is not a trivial process.

Reducer types

• Convert motor rotary motion to linear motion.

Many machines such as machine tools and

gantry robots require this type of motion. The

required speed conversion is always part of

the process. Common methods include lead-

screws, rack and pinions, belts and chains

• Drive rotary loads with suitable speed change.

Applications include rotary tables, machine

spindles and robot arms. Apart from gearhead

boxes, motors can drive loads via belts (usually

toothed) or chains

Linear drives

A small number of applications suit the use of

linear motors. The moving carriage interacts with

stationary guideway magnetically. At present, ap-

plications are restricted to high speed low inertia

systems such as pick and place machines.

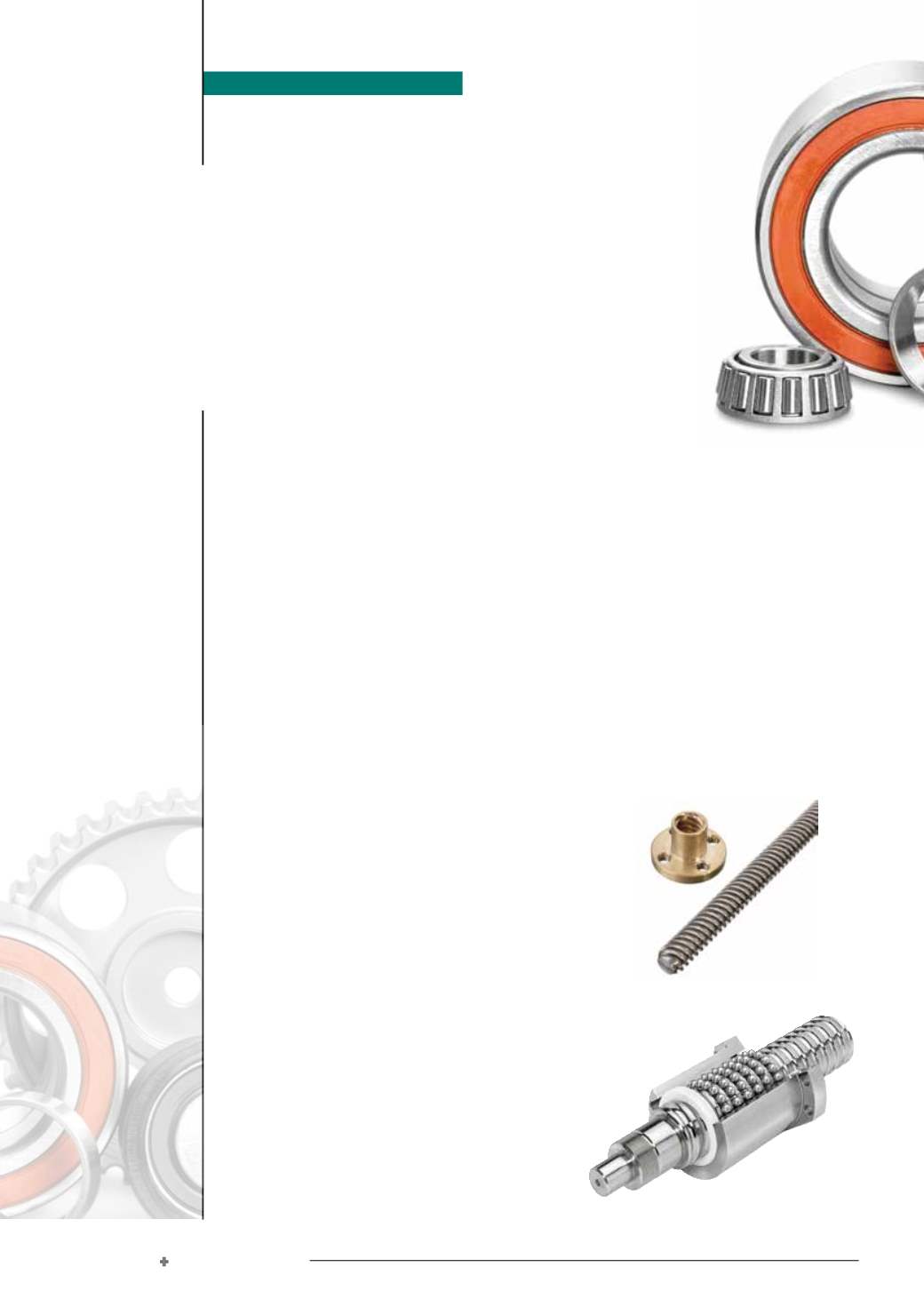

Leadscrews

These are widely used to convert rotary input to

motion linear displacement.

•

Figure 1

shows a typical leadscrew arrange-

ment. Screws are usually steel (ferrous or

stainless) with nuts made from bronze or

self-lubricating plastics such as Acetal. The

screw thread can be rectangular, but trapezoi-

dal types are more common. Efficiencies are in

the range of 35% to 80% depending on mate-

rial used and lubrication.

•

Figure 2

shows a ballscrew and nut. In this

case the sliding contact between the screw

and the nut is replaced by the rolling action of

the recirculating balls in the nut. Efficiencies

are now in the range of 85% to 95%

Figure 1: Lead screw.

Figure 2: Ball screw.

Applying Speed

Reducers

to

Mechatronic Systems

Glyn Craig, Techlyn

The term mechatronics unites various engineering disciplines such as mechanics,

electrical, electronics and computer engineering.

DRIVES, MOTORS + SWITCHGEAR