Petrochemicals

5

Chemical Technology • June 2015

COVER STORY

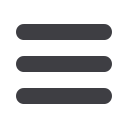

In the production of chlorine and caustic soda

solution, ThyssenKrupp Uhde Chlorine Engineers

energy-efficient and environment-friendly, ‘Uhde

BMSingle Element’ membrane technology, as well

as the BiTAC family electrolysers, are leaders. New

plants as well as revamps or conversions, which

together have a total annual capacity in excess of

40 million tonnes of caustic soda solution, provide

ample proof of this.

The new global setup will be rolled out over the

months to come. An increased presence worldwide

will be achieved by synergising the company’s

worldwide capabilities for engineering, procure-

ment and construction of high-efficiency electroly-

sis plants, as well as offering leading technologies,

comprehensive solutions, technical support and

sales. Headquartered in Dortmund, Germany,

the company is also represented in locations in

Okayama, Tokyo, Shanghai, Milan and Houston.

Invention that increases energy

efficiency

The NaCl-ODC electrolysis technology marketed

by ThyssenKrupp Uhde Chlorine Engineers offers

numerous benefits including, most importantly,

a reduction of energy consumption of up to 30 %

compared to conventional membrane-based tech-

nology; ecologically valuable solutions because of

corresponding CO

2

emission reductions; and full

compatibility of electrolysis cells and the brine cycle,

which allows for a combination of both technologies

in one plant.

The NaCl-ODC electrolysis process differs from

the conventional membrane process which results

in a reduction of the cell voltage from about 3 V to

2 V. Consequently, the ODC technology cuts the

energy consumptionby at least 30%; or alternatively,

at constant energy consumption, a corresponding

capacity increase is possible. As a result, the ODC

technology is ecologically valuable and supports

clients’ sustainability. By saving energy, clients will

indirectly realise significant CO

2

emission reductions.

In conclusion

At the close of our meeting, Vishal Harichund

summed up the implications of these changes:

“The successful conclusion of this latest joint

venture is further indication of our commitment

to supplying world class engineering and innova-

tive solutions to our clients. The wide application

of chlorine and caustic soda in pulp and paper,

water treatment, inorganic chemicals, organic

chemicals and detergents, along with a number

of innovative target market products and services

under development across the TKIS technology

portfolio, strongly suggests that this industry

presents attractive growth.

“TKIS SA, the local organisation of our Germa-

ny-based parent company, is well-positioned to of-

fer this market cost-effective, high-tech solutions

associated with an innovative EPC contractor.”

For more information,

contact Vishal Harichund on

+27 11 236 1000.

Customer: Yantai Juli

Location: Laiyang, China

Capacity: 100 000 t/year of Cl

2

Process: HCl-ODC Electrolysis

Technology

Customer: Bayer MaterialScience

Location: Krefeld-Uerdingen, Germany

Capacity: 20 000 mt/year of Cl

2

Process: NaCl-ODC Electrolysis

Technology

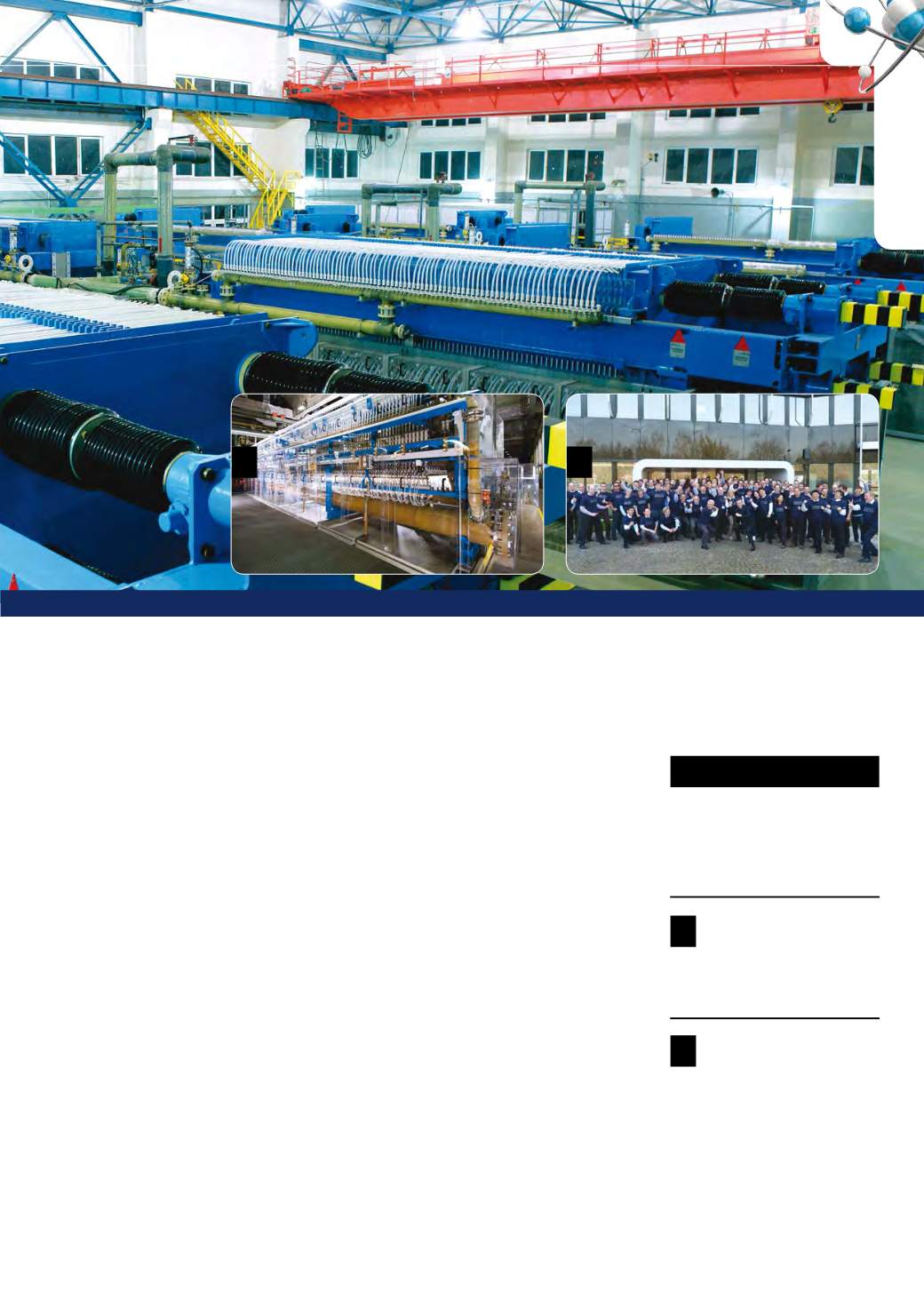

The entire team of the Uhde

Chlorine Engineers Group on

April 7, 2015 outside Harpen

House, their Dortmund-based

headquarters. All the local or-

ganisation representatives were

present for the launch of the

Joint Venture, as well as all the

representatives from the main

Uhde Chlorine Engineers entities.

Dr Sami Pelkonen, CEO, Shinji

Katayama, CTO; Keisho Cho, MD-

UCES are all in the front row.

1: Main image

2

3

2

3