WHEN — Q3 2014

Dayton Parts LLC

(continued from page 7)

Regards,

Steven S. Wolf

Axle Group Product Manager

Dayton Parts, LLC

Dayton Parts, LLC

• PO Box 5795 • Harrisburg, PA 17110-0795 • 800-233-0899 • Fax 800-225-2159

Visit us on the World Wide Web at

www.daytonparts.comDP/Batco Canada

• 12390 184th Ave. • Edmonton, Alberta T5V 0A5 • 800-661-9861 • Fax 888-207-9064

8

Look for the Part 2 continuation

of this edition of

WHEN

in the

Q4 Dayton Parts Distributor Mailing

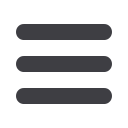

0

10

20

30

40

50

60

70

80

90

100

110

120

Pressure (psi)

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

2

12

Initial Lining Temp (Deg °F)

Recovery Stops

4

14

6

16

8

18

10

20

Actual Wheel Load (lb) — 11451.7

2

Actual Inertia (slug/ft ) — 950

Brake Type — Meritor Drive

Rolling Radius (in) — 19.6

Slack Adjuster — Haldex 5.5"

Air Chamber — MGM 3030

Brake Drum — Webb 66864

Dayton Parts

DP23 Friction Material

Link Testing Laboratories, Inc.

DrumTemperature

Air Pressure

Brake Recovery

Brake Recovery

– (continued)

Here’s what a typical brake recovery graph looks like.

This part of the test tells us if the friction material

can continue to create sufficient torque after it has

been subjected to higher drum temperatures. The

20 psi minimum is really a mute point now that ABS

is once again mandated

(more about that in Part 2).

One last side note here. While reading through how

this test is conducted, the ability of the brake drum

to dissipate heat in a sufficient manner becomes

very obvious. You would not get the same results

shown in the charts here with a

“value”

drum.

In closing remember this test is only required for

friction materials that are seeking OE approval.

Aftermarket friction materials are not required to

have this test done in order to be sold. Most

aftermarket friction material manufacturers do have

this test done on their own accord which is good.

Never purchase any friction material where this test

cannot be supplied. In the next edition we’ll pick up

where we left off around 1980 and go to the present

plus a look beyond.

As always I hope you found this edition of WHEN

informative.