COVER STORY

February 2015

MODERN MINING

17

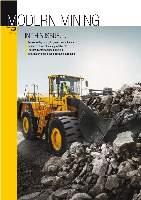

David Vaughan, Sales

Director – Equipment,

Babcock, pictured with the

Volvo L350F loader.

Powered by a 394 kW

Volvo engine, the Volvo

350F loader is an ideal

machine for tough mining

environments.

The complex will include offices, workshops

and a sophisticated rebuild centre able to

refurbish all machines in the Volvo range.” He

notes that construction of the new premises is

well advanced with occupancy scheduled for

August this year.

Vaughan says Babcock has also been

strengthening its footprint in the Southern

African region and has opened a new branch

in Matola in Mozambique and established

branches in Namibia and Botswana, which

were previously served by independent deal-

ers. In Zambia, one of its key markets, it has

branches in Kitwe, positioned at the centre

of the Copperbelt, and in Lusaka, Zambia’s

capital. It has also expanded to Solwezi in

recognition of the fact that the centre of grav-

ity of the Copperbelt has been shifting further

to the north-west of Zambia in recent years

with the opening of new copper mines such

as Kansanshi and Lumwana in North-Western

Province – with a third major mine, Sentinel,

in this same area now in the commissioning

phase.

One of the biggest sellers in the Volvo line-

up marketed by Babcock is the Volvo ADT,

which comes in three different models locally,

the 30-ton payload A30, the 35-ton A35 and the

40-ton A40. The Volvo ADT is reportedly the

global market leader and has proven extremely

popular in South Africa and neighbouring

states, with the A40 in particular being a best

seller. The models available in Southern Africa

are from the F-Series and the A40F, first intro-

duced in 2010, was the recipient in 2012 of the

‘red dot’ design award, probably the most pres-

tigious design award in Europe and arguably

the world.

According to Vaughan, one reason for the

popularity of the Volvo ADTs is the incredible

longevity they offer, with many units in the

local market having clocked up over 30 000

hours. “The Volvo haulers can soak up the

hours,” he says. “In addition,

they’re noted

for their fuel efficiency, which we believe is

market leading, and the high standards of safety

they offer. The range is also feature rich. To take

just one example, all Volvo ADTs are equipped

with Volvo’s unique Automatic Traction System

(ATC), which automatically selects the optimal

drive system to suit underfoot conditions.

“In normal mode, ATC selects the fuel-sav-

ing 6x4 drive configuration, only switching to

6x6 drive when more traction is needed. The

resulting fuel savings can be very substantial –

up to 6 % by Volvo’s estimates. There is also,

of course, a beneficial impact on tyres with tyre

life potentially being extended by up to 10 %.”

Vaughan points out that the reputation of

the Volvo ADT is such that used machines are

in huge demand worldwide. “The Volvo ADT

is almost like an international currency,” he

says. “We find that the ratio of the number of