COVER STORY

February 2015

MODERN MINING

19

machines we trade in

compared to the number

that we sell is completely

different to the indus-

try average – a result of

customers selling their

machines directly, par-

ticularly to international

buyers, rather than trad-

ing them in when they

need to modernise or

expand their fleets.”

While the Volvo ADT

accounts for the big-

gest portion of the Volvo

construction and min-

ing machines marketed

locally by Babcock, the

overall range includes

hydraulic excavators,

wheeled loaders, back-

hoe loaders (also known

as TLBs) and compac-

tors. The excavators

– eight models are offered

– range from a 5,5‑t mini-

excavator through to the top-of-the-range

70‑ton EC700 while the 11 loaders available

have bucket capacities from 0,7 m

3

to 6,8 m

3

.

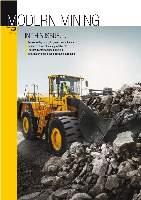

Says Vaughan: “If we’re talking mining, the

most popular models are the EC700 excava-

tor and the L350F wheel loader, which is an

extremely productive unit designed for use in

the toughest mining environments.” He adds

that the EC700 – powered by a 346 kW Volvo

engine – is well matched to the A40 hauler. As

regards the L350F, rated at 394 kW, he describes

it as an “uncompromising machine” which, like

all other units in the Volvo range, offers excel-

lent safety, ease of maintenance and durability.

Among other things, it features an intelligent

load-sensing hydraulic system consisting of

two variable piston pumps which provide

exactly the flow rate and pressure demanded

by the work situation.

Complementing the Volvo range, Babcock

also distributes the SDLG range of equipment,

which includes loaders and graders. Explaining

the positioning of SDLG with respect to the

Volvo brand, Vaughan says the SDLG machines

cater for the value end of the market, where

there is less emphasis on high-tech features.

“They are excellent machines and are proving

extremely popular with customers who do not

need the sophistication and ultra-high specs of

the Volvo range,” he observes.

An interesting point is that Volvo CE

announced in November last year that it would

be discontinuing production of Volvo-branded

backhoe loaders and graders. In future, it said,

these products would be manufactured by

SDLG in China rather than at Volvo factories

in Europe, the USA and Brazil. Said Volvo CE

in its statement: “The current product lines

of technologically advanced and high spec

Volvo-branded backhoe loaders and motor

graders have addressed a relatively small pre-

mium segment of the market. SDLG-branded

backhoe loaders and motor graders will bet-

ter serve customer demands in the large and

growing value segment of the market.”

Commenting on this decision, Vaughan says

the message he would like to convey to custom-

ers is that Babcock can continue to meet their

needs as it has in the past, with no diminish-

ment in the range of machines it is able to offer

customers.

Summing up, Vaughan says that Babcock has

successfully established the Volvo CE brand

in South Africa since acquiring the agency in

2000, with sales increasing many times over

during this 15-year period and with just over

7 500 machines now operating in the field “Our

performance has been so strong that we’ve been

named as the Volvo CE ‘Dealer of the Year’ on

three occasions,” he says. “As I’ve said, cur-

rent market conditions are challenging but we

emerged from the downturn of 2008/2009 in

very good shape and I’m confident that we’ll

do the same this time around.”

Another view of the EC700

excavator. The machine has

proven popular in Southern

Africa with customers in the

mining field.