UPM Annual Report 2016

UPM Annual Report 2016

60

61

In brief

Strategy

Businesses

Governance

Accounts

Stakeholders

CONTENTS

Wood is the primary raw material

UPM is both a major forest owner and a purchaser of wood. UPM sources

all wood assortments to ensure the optimal utilisation of this valuable

rawmaterial.

In 2016, UPM sourced 27.8 (26.1) million cubic metres of wood

globally. The majority of wood is purchased from private forest owners

who numbered over 25,000.

A network of local entrepreneurs is responsible for UPM’s harvesting,

logistics and forestry operations. Wood Sourcing and Forestry in Finland

indirectly employs approximately 2,000 persons via entrepreneurs.

In 2016, Wood Sourcing and Forestry trained its 45 key contractors

in Finland in business management. The trainings will continue in 2017.

Tracing the origin of wood is a prerequisite for UPM

All wood UPMuses in its products is legal and comes from sustainably

managed forests. UPM does not accept mixed tropical hardwood from

rainforests, nor does it accept wood from plantations that have been

established by destroying rainforests. UPM does not source wood in

areas where indigenous peoples’ rights are not respected.

All wood is covered by a third-party verified chain of custody

certificates under the FSC® and PEFC™. In 2016, 84% (84%) of the

wood used in the UPMmills is certified.

UPM verifies that the wood rawmaterial supplied to its mills is

procured according to the requirements of EU Timber Regulation,

the US Lacey Act and other regional jurisdictions. The Finnish

authorities audited UPM’s compliance with the EUTR regarding the

deliveries of chips fromRussia and the same was done for the pulp

fromBrazil by the German authorities.

Aiming at continuous improvement together with

pulp and other paper raw material suppliers

UPM buys approximately 1.8 million tonnes of chemical pulp from

external suppliers. Specific requirements are set for pulp suppliers with

regard to environmental performance, social responsibility, forestry,

wood sourcing and performance reporting.

Collecting and analysing the environmental and social performance-

related data of UPM’s pulp and chemical suppliers is an integral part of

the company’s supplier risk and performance management. Based on

the results of these analyses, the development plans are made together

with the suppliers.

In 2016, UPMRaflatac invited the best performing suppliers to

participate in the Label Life Award competition on corporate

responsibility. The award recognises UPMRaflatac’s suppliers’ efforts

in achieving good environmental and social performance and generates

further co-operation among the participating companies.

Since 2012, UPMPaper ENA and UPM Specialty Papers have

conducted a Supplier Performance and Responsibility Survey to follow

responsibility of their key suppliers. In 2016, 42 key suppliers were

evaluated and some 170 improvement proposals were identified.

To motivate its suppliers to further improve their performance,

UPM awards the most responsibly performing suppliers annually.

The packaging supplier Paul & Co. received the UPMBest in category

supplier award for the second time in a row.

UPM uses significant amounts of recovered paper

UPM is the world’s largest user of recovered paper for the production

of its graphic papers, consuming 2.8 (3.1) million tonnes of recovered

paper in 2016. The share of recycled fibre represents one third of all

fibre rawmaterials used in UPM’s paper production.

The efficiency of paper recycling depends on how the local

infrastructure for national collection schemes works. UPMpurchases

its recovered paper from local authorities, waste management

companies and printing houses, all of which are located close to the

mills in Europe. This is how UPMmaximises cost efficiency and

minimises environmental impact.

Energy from renewable sources

UPM is both a significant purchaser and producer of energy. The

majority of electrical and thermal energy is used for pulp and paper

production. UPM favours a wide range of low-emission energy sources

and focuses on energy efficiency and energy savings in its businesses.

In 2016, 69% (67%) of the fuels used by UPM came from renewable

sources.

In addition to UPM’s own electricity generation, electricity is also

purchased from the energy markets.

Logistics form the foundation for on-time deliveries

UPM delivers approximately 1.3 million truckloads (c. 25 tonne each)

of products and rawmaterials around the world every year; that is one

load every 25 seconds. Of all UPM deliveries, 66% are transported by

rail and road and 34% by sea. The majority of UPM’s haulage is handled

by contract partners. UPM aims to create strategic long-term alliances

to create benefits for the company and its customers.

UPM considers cost efficiency and environmental aspects in its

transport operations. For example, the transport services are purchased

from environmentally advanced contractors using low-emission

vehicles and transport payloads are optimised.

Wood sourcing and logistics services have a significant socio-eco

nomic impact on the rural areas where UPMmills are located. In total,

5,350 harvester drivers, 5,500 truck drivers and 820 rail-road workers

work indirectly or directly for UPM. The number of entrepreneurs and

companies involved is 860. These numbers combined with purchases

from private forest owners significantly support local livelihoods in

rural Europe, the US and Uruguay.

Out of a total spend of EUR 3.3 billion for UPMprimary raw

materials —wood, pulp and recovered paper — 68%was purchased

from local suppliers.

Transparent supplier requirements

are the basis for responsible sourcing

UPM’s supplier risk assessment covers financial, quality, environ

mental, social, economic and delivery related risks.

Based on the risk assessments, UPM selects the suppliers whose

performance is assessed in more detail. UPMuses tools such as annual

questionnaires, audits and joint development plans. In 2016, UPM

Sourcing function provided comprehensive risk assessment training

to key personnel as well as training on operational health and safety

issues to personnel visiting suppliers’ production units regularly.

The human rights-related risk assessment of the supplier base has

been enhanced since 2013. Consequently, the number of risk assess

ment-based supplier audits has increased with a comprehensive geo

graphical coverage. Some of the audits covered the entire upstream

supply chain.

In case of any non-conformance, the supplier is required to take

corrective actions. UPM follows the progress and supports the supplier

to develop its performance, when needed. However, no significant

negative impacts have been identified.

Read more on UPM Code of Conduct on p. 14,

UPM’s added value to Finnish economy on p. 54and

UPM’s value creation on p. 70-71.SUPPLY CHAIN RISK MANAGEMENT ENHANCED

The purpose of supplier selection process and the audit is to

ensure compliance with UPM’s requirements. Using external

experts has improved the quality of the audits, especially in

environments where accurate knowledge of local language

and legislation is important.

UPM’s audit partner in China is SGS, the world’s leading

auditing, verification, testing and certification company.

“Typically, the focus has been on occupational health and

safety and environmental issues”, says Tony Yang, the expert

in charge of UPM audits at SGS.

“During the audits, we assess, for example, the measures

UPM’s subcontractors take to maintain their facilities, the

firefighting equipment available or how first aid training

is carried out. Meanwhile, we also make sure that the

subcontractors comply with the local and international

regulations and UPM’s requirements”.

Based on risk assessment, UPM defines the areas for the

audit. The auditor is then responsible for conducting the

audit and reporting the results. UPM’s responsibility is to

ensure the suppliers address any found issues as required.

Read more:

www.upm.com/responsibilityWOOD DELIVERIES TO UPM MILLS

1,000 m

3

2016

2015

Finland

18,619

17,697

Germany

2,030

1,543

Austria

1,297

1,013

United Kingdom

368

271

Russia

344

272

Estonia

165

135

United States

544

867

Uruguay

4,469

4,293

Total

27,776

26,090

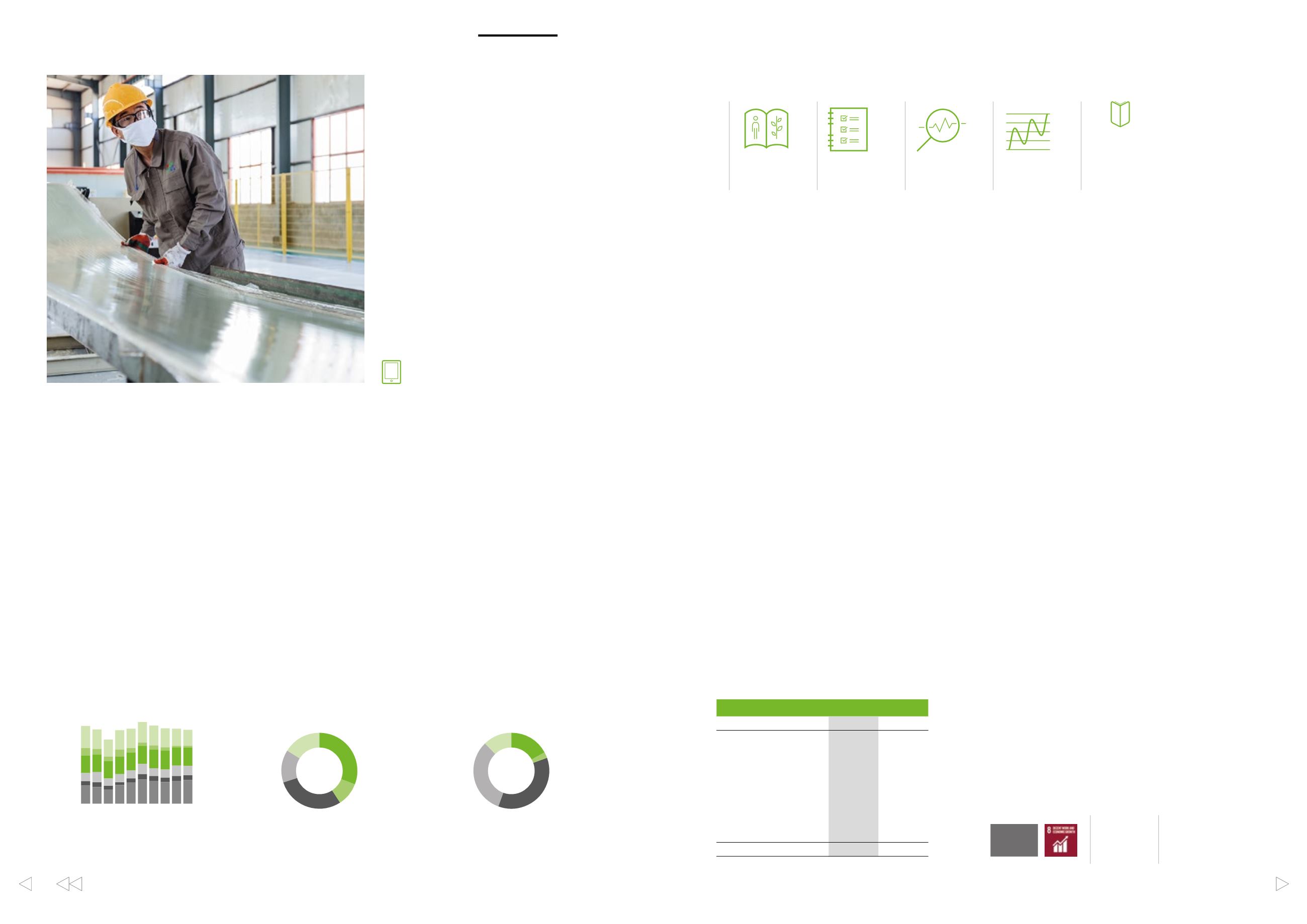

11 12 13 14 15 16

07

10 09 08

20

16

12

8

4

0

■

Market purchase

■

Condensing, shareholdings

■

Nuclear, shareholdings

■

Hydro, shareholdings

■

Hydro

■

CHP

Electricity sourcing

TWh

Company forests

17%

Import 12%

Private forests

32%

State forests 3%

Delivered sale/

incl. sawmills 36%

Sources of wood to UPM mills 2016

Fibre 31%

Logistics 16%

Energy 10%

Raw materials 29%

Indirect

materials and

services 14%

UPM’s external purchasing spend

Continuous

supplier

development

Compliance

Transparent

supplier

requirements

Systematic risk

assessment

IMPROVED FINANCIAL

PRFORMANCE

UPM Responsible Sourcing fundamentals

94%

TARGETS

2030

of raw material spend

qualified against

UPM Supplier Code