UPM Annual Report 2016

UPM Annual Report 2016

66

67

In brief

Strategy

Businesses

Governance

Accounts

Stakeholders

The goal of international climate policy is to keep the global average

temperature rise at a level that does not threaten nature and society.

Achieving the goal requires significant reductions in emissions across

the globe. Developing means for adapting and preparing for climate

change is also necessary.

UPM’s Biofore strategy meets the challenge set by climate change

on many levels:

Sustainable forestry

•

We ensure that our most important rawmaterial, wood, grows

in forests that are sustainably managed and act as carbon sinks

•

We promote biodiverse ecosystems that are less vulnerable to the

impacts of climate change

Responsible production

•

We promote resource efficiency by making more with less

•

We utilise the best available techniques (BAT) in our production

•

We continuously increase the share of renewable and low-emission

energy in our operations

Renewable and recyclable products

•

We replace non-renewable materials with renewable materials,

and our products store carbon

•

We innovate new business and products for future needs

UPM’s energy production is based on versatile energy

sources

UPM is a significant energy producer. The company favours the use

of renewable and other carbon-neutral energy sources and the use of

natural gas. Biomass-based fuels account for 69% (67%) of the fuels

used. UPM is the second-largest generator of biomass-based electricity

in Europe.

Paper and pulp mills, which use power and heat in their production

processes, represent the majority of UPM’s total energy consumption.

Climate actions and energy efficiency

Most of the energy is consumed in the manufacture of mechanical pulp,

pumping and paper drying. At all pulp and almost all paper mills, steam

and electricity are generated simultaneously by combined heat and

power (CHP) plants. At some mills, all or some of the energy is produced

by external and co-owned power plant companies.

As the use of weather-dependent energy sources increases, the need

for balancing power in energy systems will also grow. UPM is investing

in hydropower, the most effective and sustainable method of producing

balancing power. The new unit of the Harjavalta hydropower plant was

completed in September.

The project provides new possibilities for managing the water flow

rate in the Kokemäenjoki and, as a result, decreases the risk of flooding.

As part of the renovation project, facilities for a fish hatchery have been

built at the power plant. Hatcheries play an important role in

maintaining the populations of migratory fish species in rivers with

man-made structures.

UPM strives to continuously improve energy efficiency across all its

operations. For this purpose, UPMhas set a new continuous target to

improve energy efficiency by 1% annually. During the last 20 years,

energy efficiency in production has significantly improved due to energy

audits, innovations and internal campaigns. Electricity consumption

per tonne of paper has decreased by 14% over the past 10 years. As a

result of the energy-saving actions carried out in 2016, UPM reduced its

energy costs by EUR 1.9 (1.2) million, avoided 18,000 (8,100) tonnes of

CO

2

emissions and achieved a 49,000 (32,000) MWh reduction in energy

consumption. The annual savings were EUR 2.0 (1.7) million, 17,300

(13,000) t CO

2

and 92,000 (51,000) MWh.

In October 2016, UPMwas included in the CDP Climate A List.

UPMhas featured in the CDP Climate Index for eight consecutive years

as a result of its climate actions and transparent climate reporting.

CONTENTS

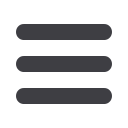

SOLAR SUCCESS FOR UPM SHOTTON

The construction of the UK’s largest solar park at Shotwick, Cheshire,

adjacent to the UPM Shotton paper mill, has brought yet another

opportunity for UPM to deliver on its 2030 renewable energy target

to reduce fossil CO

2

emissions by 30%.

Solar power is a highly efficient method of energy production with

zero moving parts, meaning maintenance is kept to a minimum. Using

the latest in both photo-voltaic panels and cutting edge conversion

technology, the plant can produce on average 65 MWh/year.

A direct link to UPM Shotton’s own infrastructure means that the paper

mill can operate on 100% renewable energy during daylight hours.

The start-up of its second steam turbine, utilising excess steam from

its biomass combined heat power plant (CHP), in December 2016,

means the mill will be on track to meet its own energy efficiency targets

and significantly contribute to UPM Group’s 2030 responsibility targets.

UPM Shotton’s transition to 100% renewable energy started in 2006

with the start-up of its CHP. With a focus on energy efficiency, the mill

has continued to reduce its use of fossil fuels from the national grid.

The solar park development means it will reduce its purchase of power

to almost half.

Read more:

www.upm.com/responsibility11 12 13 14 15 16

07

10 09 08

20

16

12

8

4

0

■

Total SO

2

■

Total NO

X

Paper production

Chemical pulp production

UPM’s acidifying flue gases

20

16

12

8

4

0

1,000 t

mio t

11 12 13 14 15 16

07

10 09 08

8

6

4

2

0

■

CO

2

from purchased electricity

■

CO

2

from on-site energy generation

Paper production

Chemical pulp production

UPM’s fossil carbon dioxide emissions

16

12

8

4

0

mio t CO

2

/a

mio t

In 2016, on-site CO

2

emissions

(Scope 1) decreased mainly because

of change in energy supply at UPM

Hürth mill. CO

2

of purchased electricity

(Scope 2) increased mainly due to

higher CO

2

factors in Germany and

Finland.

In 2015, reduction was achieved

mainly due to investment in flue gas

purification at UPM Changshu paper

mill. In 2016, increase of NOx was

mainly due to the production increase

of chemical pulp.

ELECTRICITY GENERATION THROUGH OWN

POWER PLANTS AND SHAREHOLDINGS

TWh

2016 2015

Mill CHP

6.1

5.9

Hydropower

3.6

3.9

Nuclear power

4.7

4.7

Condensing power

0.5

0.4

Total

14.9 14.9

FUELS USED FOR HEAT GENERATION

TWh

2016 2015

Black liquor

19.7 17.6

Bark and other biomass

9.1

8.5

Heat recovered from TMP production

1.3

1.4

Renewable fuels total

30.1 27.5

Peat

1.0

1.1

Purchased heat

1.0

0.7

Natural gas

8.1

8.3

Oil

0.6

0.6

Coal

3.4

3.0

Total

44.2 41.2

CAPACITY TO GENERATE POWER THROUGH

OWN POWER PLANTS AND SHAREHOLDINGS

Nominal MW

Hydropower

722

Nuclear power

581

Condensing power

191

UPM Energy in total

1,494

Mill site combined heat and power (CHP)

1,415

Mill site hydropower

49

Mill site power generation in total

1,464

Total UPM

2,958

Reduction in acidifying

flue gases since 2008

24%

TARGETS

2030

Renewable

fuels share

69%

TARGETS

2030