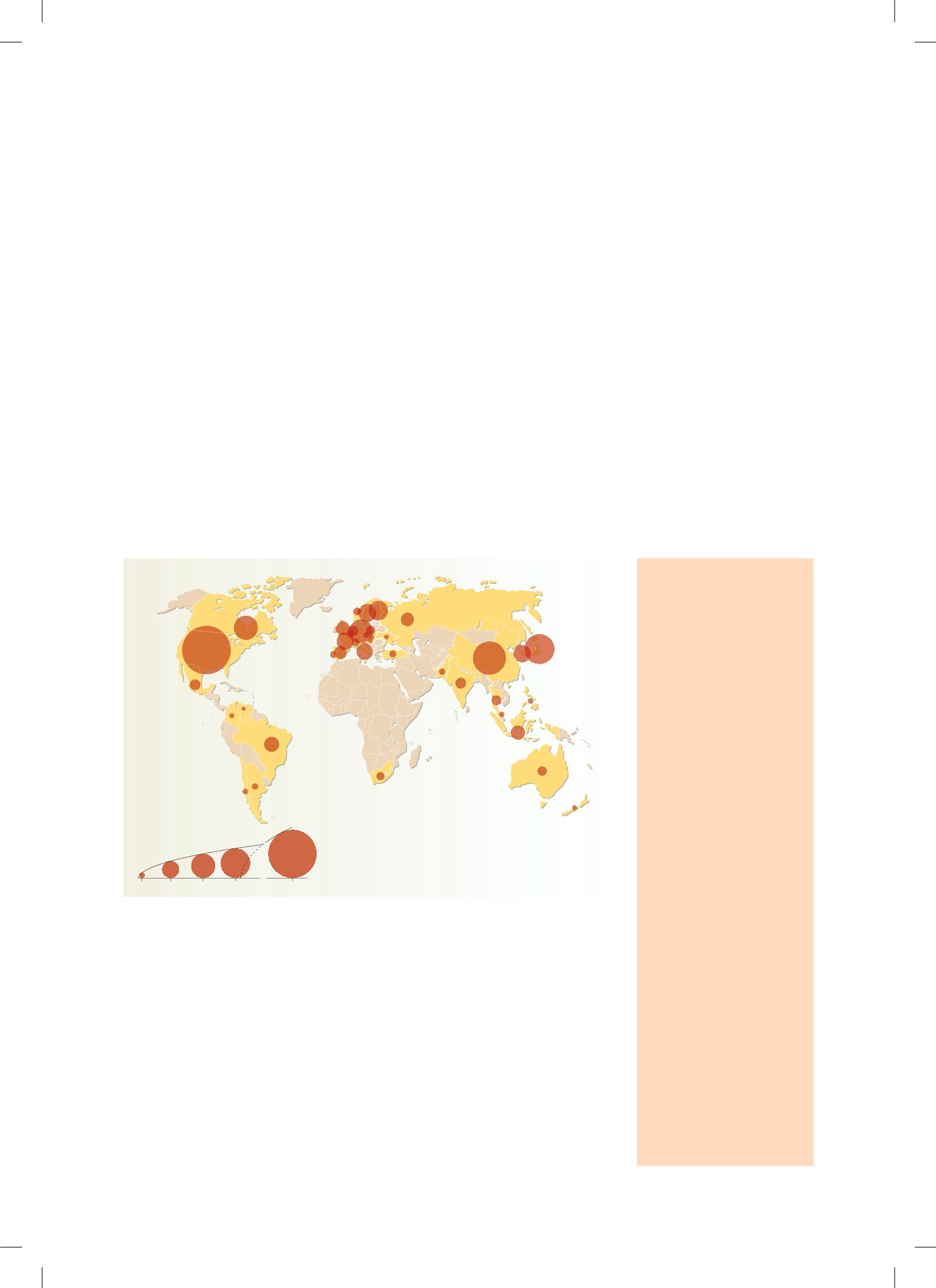

Millions tonnes

(producers above

500 000 tonnes only)

Paper and paperboard production

10

1

30

20

80

Includes all types of paper and paperboard:

newsprint; printing and writing paper; construction paper and

paperboard; household and sanitary paper; special thin paper;

wrapping and packaging paper and paperboard and all other

paper and paperboard.

Source: FAO,

Forestry Report 2003

.

MANUFACTURING WASTE

The big waste factory

Have you ever considered the volume of waste caused by manufac-

turing the little implement for cleaning your teeth? One toothbrush

causes 1.5 kilograms’ waste. About 94% of the materials extracted

for use in manufacturing durable products become waste before the

product is manufactured.

Industry is the top producer of waste in developed countries. A

large proportion of industrial waste is hazardous, because industrial

processes often involve chemicals. Cleaner production – reducing

the amount of problematic components in a product and additives

used in the production process – waste avoidance anda life cycle

approach to waste management are attempts in the right direction.

For some, this is not enough: they promote a complete rethinking of

material use – only use components that have a positive influence

on the environment! There is talk of a “new industrial revolution” and

‘cradle to cradle design’.

Waste water stains on white paper

Though it is based on wood, a natural renewable resource, the pulp and paper in-

dustry is one of the worst sources of pollution. It absorbs more than 40 per cent of

all timber felled worldwide. Despite the development of digital communications tools

global paper production is expected to increase by 2.2 per cent a year from 330 mil-

lion tonnes at present to 440 million tonnes worldwide by 2015. The main growth

areas are Asia and Eastern Europe, but annual per capita consumption in Western

Europe is also expected to rise from 207 kilograms currently to 264 kilograms.

Regulations and legislation introduced in Europe and North America in recent

years require improved production processes both in terms of energy consumption,

resource usage and pollution control. Bleach-free production is technically possible

now and water pollution could be cut to a minimum. Thanks to labels that com-

municate environmental standards, consumers could and should be aware of the

possibilities of choosing paper with less environmental impact.

Transferring production from Europe and North America to other parts of the world

where standards tend to be lower (China, South America) partly outweighs these gains.

Producing paper differ-

ently

The Julius Schulte Söhne

GmbH paper mill in Düsseldorf

manufactures paper from re-

cycled waste paper, with zero

effluents. Thanks to proprietary

technology the mill cleans its

own waste water and reuses

it. It thus saves some 260 000

cubic metres of water and €400

000 in sewage expenses. The

gas produced by the effluents is

scrubbed to remove the sulphur

and used to generate electricity,

covering all the requirements of

the mill.

From 2009 the Forscot mill in

Scotland plans to produce pa-

per in a fully integrated mill sup-

plied by timber from Scotland

and the north of England, de-

livered by train or boat. Waste

materials (bark, sawdust, etc.)

and effluents linked to pulp

production will be used for the

mill’s electrical power supply.

About 90 per cent of the 144

megawatt output will be used

on the spot, the rest being fed

into the power grid. Forscot

plans to produce about 970

000 tonnes of paper and pulp,

of various grades, primarily tar-

geting customers in the United

Kingdom, where demand is

high. Deliveries will be made by

rail or sea.

For an example of how waste

from the paper industry can be

reduced by reusing paper di-

rectly see pages 30–31.