117

J

uly

2008

www.read-tpt.com›

orientation with conventional ultrasonics is very difficult to sustain

on moving or bouncing materials, such as tubes under production

line conditions.

3. Online ultrasonic wall thickness

measurement with laser-ultrasonics

The above limitations are eliminated by laser-ultrasonics. In laser-

ultrasonics, laser light is used for generation and detection, at a

distance, of the ultrasonic pulse. Since no mechanical contact is

made between the sensor and the tube, the temperature of the

tube does not affect the performance of the sensor. Furthermore,

in laser-ultrasonics the source of ultrasonic generation is located

directly on the surface of the tube. The detection of ultrasounds is

made by monitoring the motion of the same surface at the same

location.

In effect, the surface of the tube becomes the sensor in laser-

ultrasonics. It can be shown that the orientation of the laser light

with respect to the normal direction to the surface of the material

does not affect the generation and detection of the ultrasonic signal.

Hence, no particular orientation between the laser-ultrasonic sensor

and the surface of the inspected material is needed. This allows

laser-ultrasonic inspection to be insensitive to the bouncing of the

tube.

Laser-ultrasonics is a combination of two separate laser methods:

laser generation of ultrasounds and laser detection of ultrasounds.

Laser generation of ultrasounds is a technique that has been in

use since the early development of pulsed lasers

[2]

. Efficient laser

generation of ultrasounds on metal is performed by applying a

strong laser pulse onto the surface of the material, which causes

ablation or vaporization of a small quantity of the material at the

point of impact of the laser. Following the ablation, a recoil force is

produced, which is the source of a compression ultrasonic pulse.

The compression pulse is always launched in a direction normal to

the free surface of the tube (ie the surface of impact of the laser

beam) independently of the angle of incidence of the laser light.

Hence, travel-time of the ultrasonic pulse is always recorded in the

direction normal to the surface, giving the correct wall thickness.

It should be recognised that for high temperature steel, the blown-

off material of the ablation is the oxide covering the surface. The

oxide is rapidly regenerated at these elevated temperatures and

therefore no visible mark is seen once the material is cooled to an

ambient temperature.

Laser detection of ultrasound is based on frequency-demodulation

by an optical interferometer of the laser light reflected or

backscattered from the surface of the material

[3]

. A laser light is

focused on (or near) the point of impact of the generation laser

beam on the surface of the material. Any surface motion at the point

of impact of the detection laser is recorded in the reflected light

as an optical frequency variation (slight change of ‘colour’). The

ultrasonic surface displacement is therefore ‘encoded’ in the laser

light, called the signal beam.

After ‘extraction’ from the signal beam, the resulting information

is identical to a conventional ultrasonics waveform, often called

A-scan in non-destructive inspection, as shown in figure 1. The

signal contains a strong initial pulse, called the ‘surface signal’,

corresponding to the initial impact of the generation laser beam on

the surface of the tube, followed by several pulses, which are the

echoes resulting from the forward propagation and reflection from

the back wall of the initial ultrasonic pulse.

The travel-time of the ultrasonic pulse within the bulk of the tube

is obtained by measuring the time between the initial surface

impact and the time of arrival of the first echo. Numerical

signal enhancement methods are used to get a high accuracy

measurement of the travel-time. The values recorded are then

scaled with the appropriate velocity of sound for the material of the

tube and corrected for thermal expansion.

It should be recognised that since velocity of sound in a material

is a function of temperature, the temperature of the tube must

also be recorded simultaneously with the measurement of the

laser-ultrasonic signal. The LUT gauge makes this simultaneous

measurement using an optical pyrometer. The temperature is

measured at the same location as the laser-ultrasonic signal. The

scaling value, used to convert travel-time to thickness, is adjusted

using the temperature measurement and the steel alloy category of

the produced tube.

The heart of a laser-ultrasonic system is the optical interferometer.

Several optical interferometers are available, each with their own

advantages and limitations. Tecnar Automation Ltee (Tecnar)

is a world leader in the development and manufacture of laser-

ultrasonics equipment, including laser-ultrasonic demodulators.

Following developments made at Tecnar, an active interferometer

approach has been developed, based on two-wave beam mixing

[4]

,

specifically for online wall thickness measurement of hot tubes in

the harsh operation of steel mill.

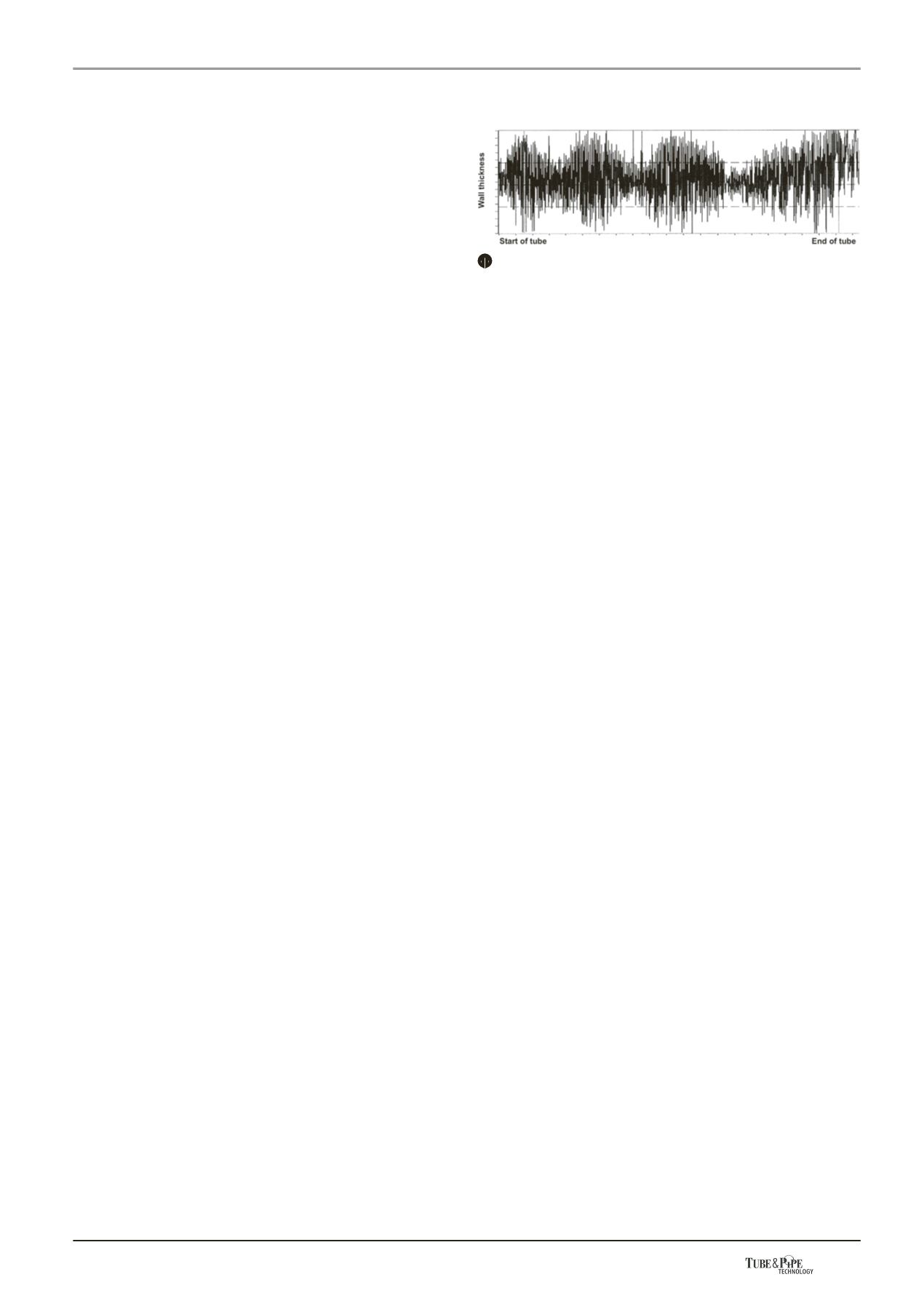

By taking wall thickness measurement as function of the length of

the tube, wall thickness length-profiles are obtained, as shown in

the figure below. The ‘signature’ of the wall thickness length-profile

is identical to the length-profile obtained with a conventional UT

system for tube, with the exception that the data shown in the figure

was obtained online and displayed in real-time.

The shape of the length-profile is used by operators to identify

the source of ‘out of specifications’ production and appropriate

correction measures can be taken. The length-profile shown in

figure 2 is typical of a tube with large eccentricity. The rapid variation

(cycle) of the wall thickness comes for the detection of minimum

and maximum wall thicknesses of the tube as it is rotated before the

LUT probe.

4. The LUT (laser ultrasonic thickness) gauge

The LUT gauge is the latest implementation of laser-ultrasonic

technology for online wall thickness measurement of hot tube.

The LUT includes the most advanced laser-ultrasonic technology

Figure 2

:

On-line wall thickness measurement using LUT gauge