new products

sensors, announced the Mini-IO connector has been

adopted as an international standard (IEC 61076-3-122)

by the International Electrotechnical Commission (IEC).

IEC 61076-3-122 provides the minimum requirements

for a miniaturized connector for industrial applications

and thus ensures safety through consistent performance

and interoperability. Connector requirements for

industrial applications are high as they typically run in

harsh environments with high mechanical demands

from vibrations and rapid movements, environmental

stress through dust and humidity, and possible

exposure to radiated electromagnetic fields.

“TE is pleased that with the completion and publication

of IEC 61076-3-122, the Mini-IO is the first standardized

miniaturized industrial communication connector for

an IP20 environment. Beyond its advantages for

industrial applications in harsh environments, the small

dimensions of the connector enable smaller devices

and therefore higher packing densities inside cabinets,”

said Guenter Feldmeier, global standardization &

consortia leader of TE’s Industrial business unit. “TE

Connectivity is pleased that the mini- i/O Standard was

based on our technology.”

Referring to its current use in industrial automation

systems such as MECHATROLINK and VARAN,

Feldmeier adds: “The reliability of the Mini-IO in harsh

environments is already demonstrated by industry

users. The standard now offers an exciting opportunity

to accelerate the adoption by further eco-systems.”

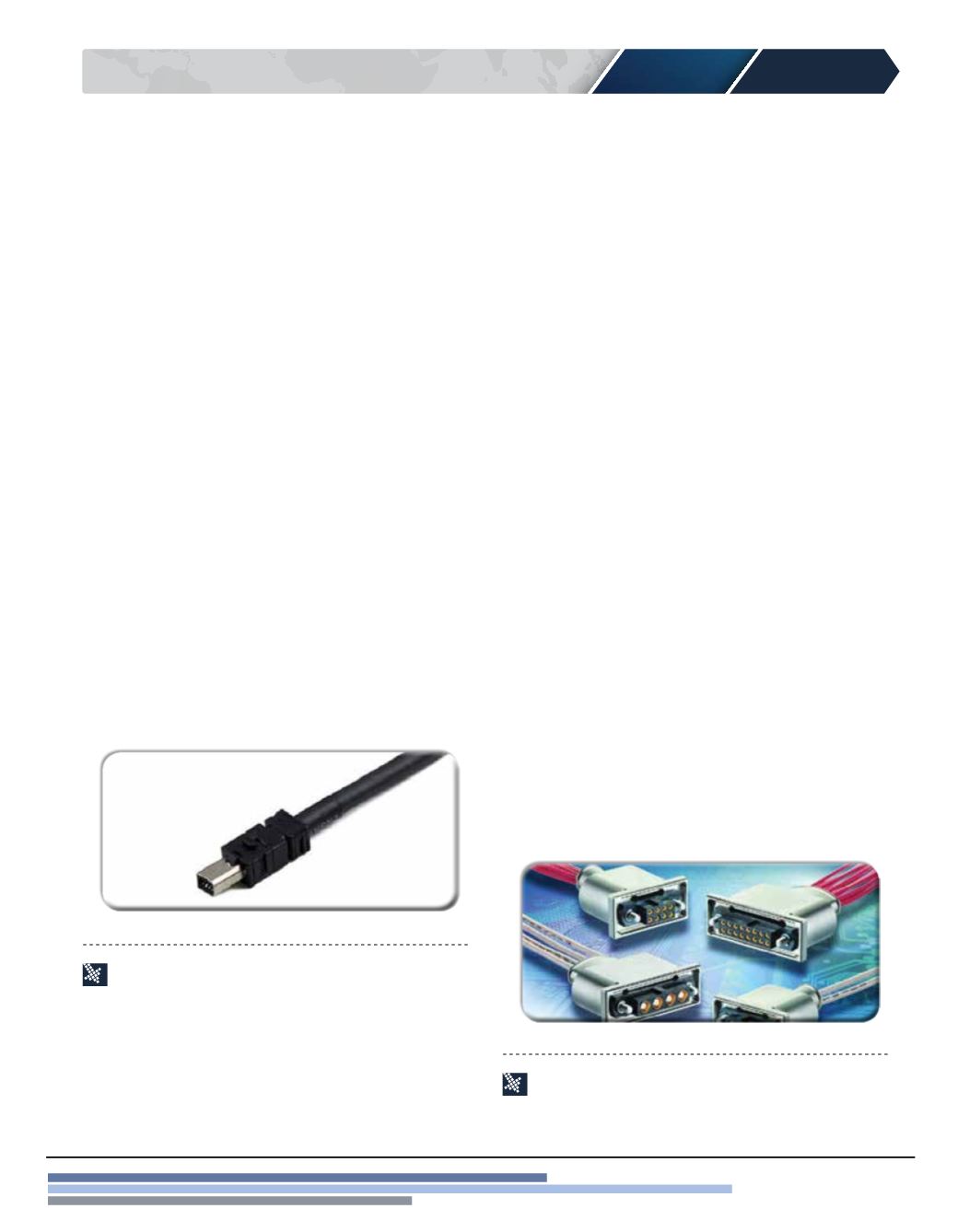

Metal Backshells with Built-In Shielding

Ensure Ongoing Electrical & Mechanical Integrity

To complement its widely-used Datamate wire-to-

board connector offering, Harwin now supplies a

comprehensive range of backshells with a rugged

aluminium alloy construction and electroless nickel

plating. Through these accessories, which can be

applied to new installations or alternatively for carrying

out mid production modifications, engineers are able

to add increased levels of mechanical robustness, as

well as providing the necessary EMI/RFI protection.

As a result, prolonged operational lifespans can be

benefitted from even in the most uncompromising of

application conditions.

Incorporated into the female cable versions is a highly

convenient attachment feature viawhichbraid screening

can be achieved with maximum effectiveness. There is

a large elliptical entry hole for braid placement, along

with a choice of slotted or hexagonal jackscrews on

either side for securing the connection (as well as

providing strain relief). The male backshell is designed

for panel mount applications, and is compatible with

both cable or vertical PCB connector styles. Full 360

degree EMI/RFI shielding is delivered once the male/

female mating process has been completed. A working

temperature range spanning from -55°C to +125°C is

supported.

The new Harwin backshells can be used in conjunction

with both the company’s J-Tek and its Mix-Tek

Datamate connector product lines – with signal,

power and coax cabling all being accommodated.

The combined Datamate/backshell assemblies are

significantly lower in overall cost than equivalent

Micro-D/backshell arrangements. Made to order,

only low minimum volumes are required and there

are very short turnaround times involved. Among the

key areas where these items will be employed are

aerospace, motorsport, industrial drives/controls,

military communication, satellite systems, robotics and

renewable energy infrastructure.

OMC launches new small-footprint SMA

Tx/Rx housings

OMC, the pioneer in optoelectronics manufacturing,

New-Tech Magazine Europe l 73