Mechanical Technology — May 2016

9

⎪

Special report

⎪

A summary of MBSA 2015/2016 results

• Total annualised revenue for the group at

R65.8-billion – 45% up on the previous year

– due to the expected increase in production

volumes out of the East London plant and

the increase in export volumes.

• Earnings before interest and tax (EBIT)

improving by 52% to end at R4.67-billion.

• With total sales of 24 608 Mercedes-Benz

cars, the company is more than 3 000 units

ahead of its nearest competitor.

• Daimler Trucks and Buses (DT&B) remained

market leaders with unit sales of more than

5 300.

• DT&B is first to market with compressed

natural gas buses and opens a new Regional

Centre Southern Africa.

• Mercedes-Benz Financial Services, with

acquisitions surpassing all records, secures

7% growth to end above R10-billion.

• A further investment of R498-million was

made in the East London C-Class plant.

Mercedes-Benz South Africa’s East London plant manu-

factured a record-number of its new W205 C-Class units

from its plant in East London, most destined for export. In

total 102 200 C-Class units rolled off the line in 2015.

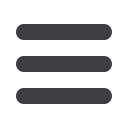

A robotic cell with a rotating jig in the MB Training Academy, designed to exactly mimic those

used on MBSA’s East London production line.

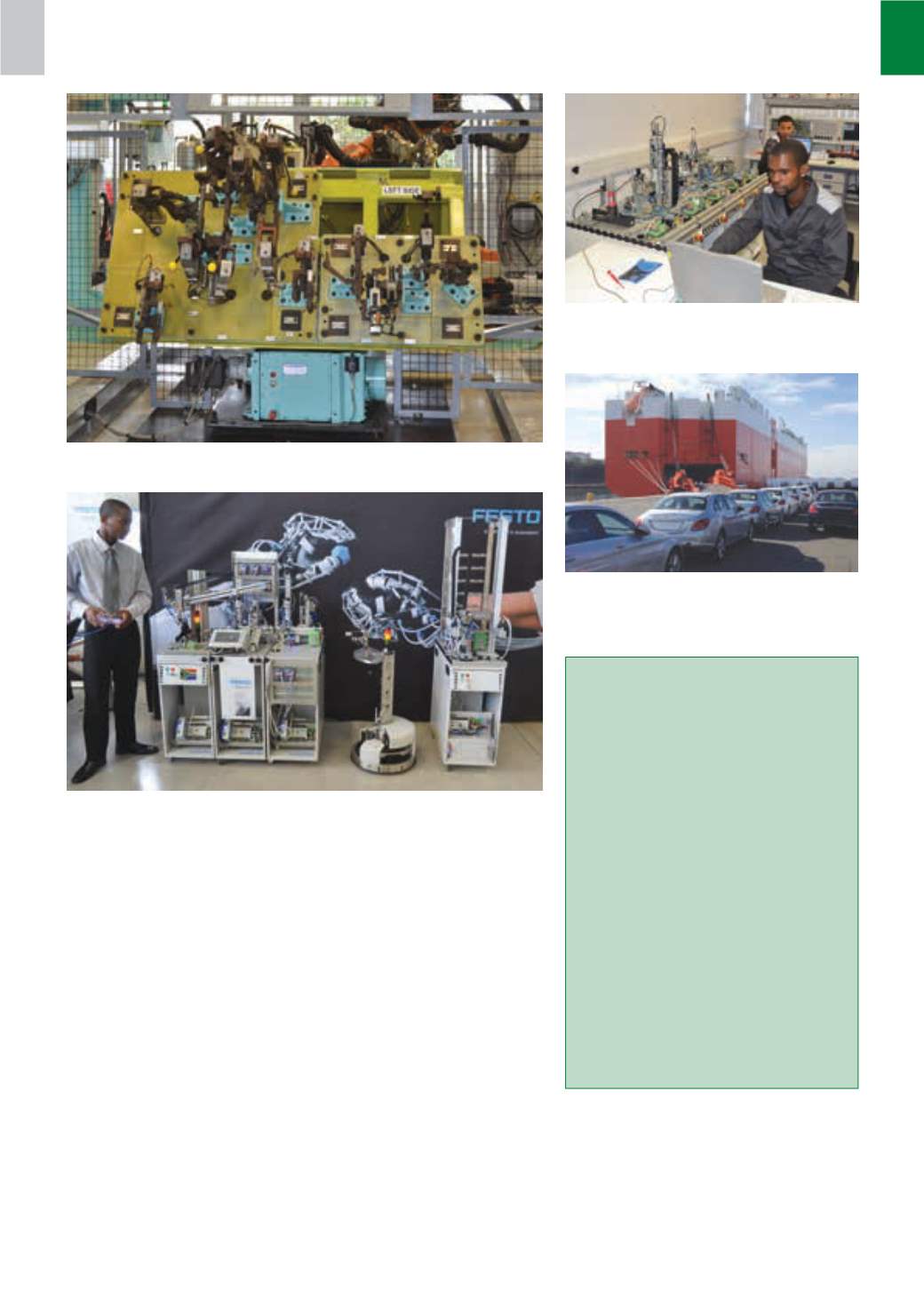

A Festo Installation being used as an introduction to robot programming.

Advanced technology training upskills existing artisans

with advanced technologies, such as mechatronics, PLCs

and automation.

industry; apprenticeships for artisans

focusing on qualified unemployed school/

college leavers; and advanced technology

training, which upskills existing artisans

with skills and advanced technologies,

such as mechatronics, robotics and

automation.

The state of the art MBLA is equipped

with cutting-edge advanced technology,

ranging from robotics and plant automa-

tion to metal joining technologies. There

is also a variety of robot cells with some

stand-alone robots as well as those

equipped with other technologies such

as grippers, weld guns, stud welders and

more. In addition, the MBLA’s automa-

tion laboratories feature programmable

logic controllers (PLCs) and simulators

together with the learning units.

MBSA is also piloting digital transfor-

mation, through virtual commissioning

technology, which is being researched.

The MBLA will develop modules and a

virtual commissioning lab, which will

enable it to offer facilities and training to

employees in industry and local assembly

line builders and systems integrators.

Benefits include: management of chang-

es in production, reduced commissioning

time and impact to production, as well

as improved proof of concept and safety.

“Being part of the group of learners

who receive training at the Mercedes-

Benz Learning Academy has been one

of the best experiences of my life. I have

been prepared for the work environment

and have established values and morals

that I can carry even beyond industry

to my own life as well. In addition, our

instructors always emphasise that there

are many people who have been here

before us that have gone on to achieve

greater things in life and this is some-

thing that inspires me to give my best,”

says 22-year old Jiovanni Bossr from

King Williams Town, one of the current

trainees at the academy.

The MBLA aims to continue unlock-

ing opportunities by providing the best

possible people development initiatives

in the region.

q