www.read-tpt.com

www.read-tpt.com

76

J

ULY

2016

AR T I C L E

Advanced Machine & Engineering/AMSAW

by Willy Goellner, chairman and founder – Advanced Machine & Engineering/AMSAW

Effect and prevention of vibration

in carbide sawing

by Willy Goellner, chairman and founder – Advanced Machine & Engineering/AMSAW

Vibration is harmful in any sawing machine, but in high

production saws with hard,

and brittle

, carbide tipped blades,

it can be absolutely catastrophic.

Reducing vibration is the main focus for machine designers,

because vibration dramatically reduces the effectiveness and

tool life of the saw blade and will increase the overall cost-

per-cut.

When vibration is controlled, however, a carbide tipped saw

blade is the optimum tool for high production sawing, because

carbide can cut much faster than other materials such as high

speed steel.

Machine designers pay close attention to certain vibration

frequencies, because not all vibration frequencies have a

damaging effect.

In this article – which is first of a three-part series – AME

focuses on the damaging effect and prevention of vibration

in carbide sawing.

As part of the team that invented the first billet saw using

carbide tipped circular saw blades and the founder of

the AMSAW machines, my design team has learned

throughout the past 50 years that success in carbide

sawing comes from a solid understanding of four factors:

vibration, resonance, damping and stabilisation.

Each component has an infinite amount of natural frequencies

and each natural frequency comes with a corresponding

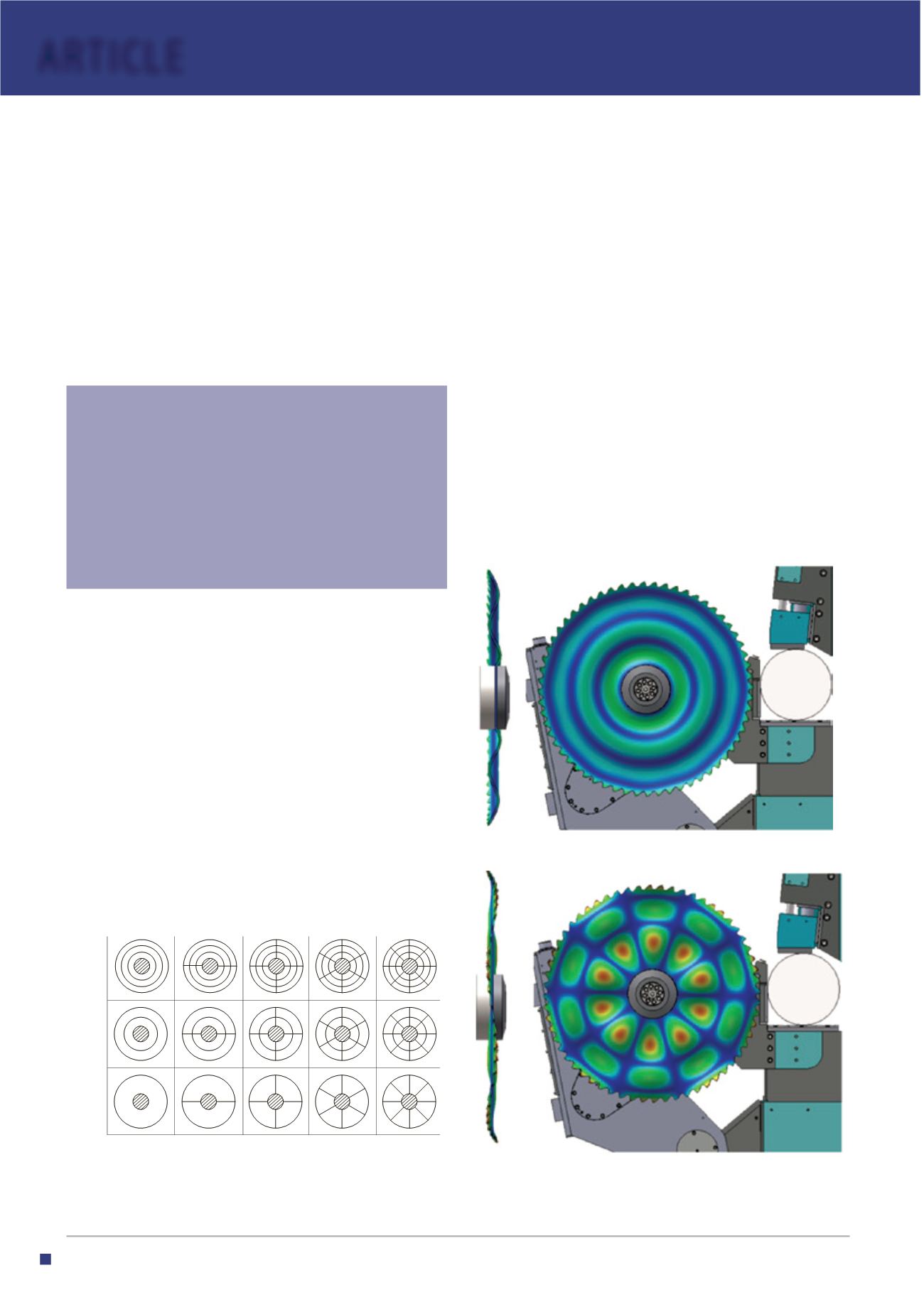

mode shape (Figure 1).

If the excitation frequency (caused by the tooth hitting the

material) matches one of the natural frequencies of the saw

blade, the blade will vibrate with the associated vibration

pattern. Only certain modes at lower frequencies have a

damaging effect on sawing.

Node circles

Node diameters

0

0

1

2

1

2

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+ +

+

+

+ +

+

+

+

+

+

+

+

+

+

+

+

+

+

+

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

– +

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+ +

+

+

–

–

–

–

–

–

–

–

–

–

–

–

– –

–

–

– –

–

–

–

–

–

–

–

–

–

–

–

–

–

–

3

4

Figure 1: Harmonic vibration patterns (modes) of circular plates.

Higher vibration frequencies have little effect and are not a concern

for machine designers

Figure 2 and Figure 3: Typical modes which include node circles and

superimposed node diameters only appear at higher frequencies

and have practically no effect on carbide sawing