www.read-tpt.com

www.read-tpt.com

78

J

ULY

2016

AR T I C L E

Dalian Field

xx

Tube mill productivity and line speed

are equally impor tant for the market

competitiveness of a tube plant

By Guowu Gao, chief engineer at FD Machinery

It is correct in theory, but it is not the same in reality: the

highest quoted line speed is applied to the smallest tube

size only, and as the tube size grows the speed is lowered

dramatically. The more the speed falls, the lower the overall

productivity. So, high nominal speed does not always mean

low productivity and vice versa.

Specialists in tube machinery design know very well that line

speed depends on the following:

1) power capacity of the forming section

2) power capacity of the HF welder

3) power capacity of the flying saw (milling saw)

There are some other elements that influence the

line speed, such as entry section, pipe collecting

section, labour intensity and so on, and the most

important are the three mentioned above.

The power of the forming section can be increased by

strengthening the mill structure, and the HF welder

capacity can be increased by raising power output.

Also, the only item that influences the speed and

can not be upgraded is the cut-off (flying saw). The

cut-off is a real bottleneck that holds down the speed

limit of the entire mill. It is possible to determine the

possible line speed by the power capacity of an HF

welder; for example for a 76mm tube mill, as you

make a 76mm/4mm tube, the line speed with a

200kW welder will be 40m/min, and a 300kW welder

will give you a speed of 60m/min. For tube mills that

use a milling saw for cut-off, the choice of a 300kW

welder is a mistake, only because the performance

For a tube mill, line speed is a very important indicator.

Normally the line speed for small mills can be up to 120-

150m/min, middle mills up to 80-100m/min and large

mills up to 40-60m/min. But in daily factory conditions

tube mills seldom run at the highest speeds. In my 28

years of experience in tube machinery construction, I

have only once witnessed a Turkish company run their

line at 150m/min on regular basis. In a debate on what

the best choice of tube mill characteristics is, many say

that speed is most important, while others argue that

speed is not important at all. This is because the most

important characteristic of a tube mill is productivity. One

may say that speed just means productivity, because the

higher the speed the better the productivity.

of the cut-off will not meet the performance of the welder in

respect of speed. (There are some technologies for making

long tubes and cutting them for desired length offline, which

there is not enough room to discuss in this article.)

Both 200kW and 300kW welders for 76mm/4mm tube mill will

provide a “nominal” speed for this mill as fast as 120 or even

150m/min, as these high speeds are applicable only to smaller

sizes of tube that this tube mill is capable of producing; the

power of this welder is enough to provide enough speed for

small tube production.

As you start making tubes with larger gauge, it is clearly

seen that by raising the capacity of the welder from 200kW

to 300kW you can raise productivity by 30 per cent. While

making a tube with thinner wall, for example 76mm/1mm, the

speed can be up to 200m/min. But the recommendation from

the equipment producer will not exceed 100m/min, otherwise

the cost of the saw blades and the productivity loss due to line

stop for blade changes will greatly exceed all the benefits of

the speed, which of course no producer would want.

We have already mentioned that in the case of using a

300kW welder for 76mm/1mm tube production, theoretically

the line speed can reach 200m/min. If all other sections of

the line (forming, cut-off, entry, packing, etc) could meet

this speed requirement, this would be the line with the

highest productivity in the world, with three to four times the

productivity of an ordinary mill. We may also say that a line

with this high productivity saves three to four times on labour,

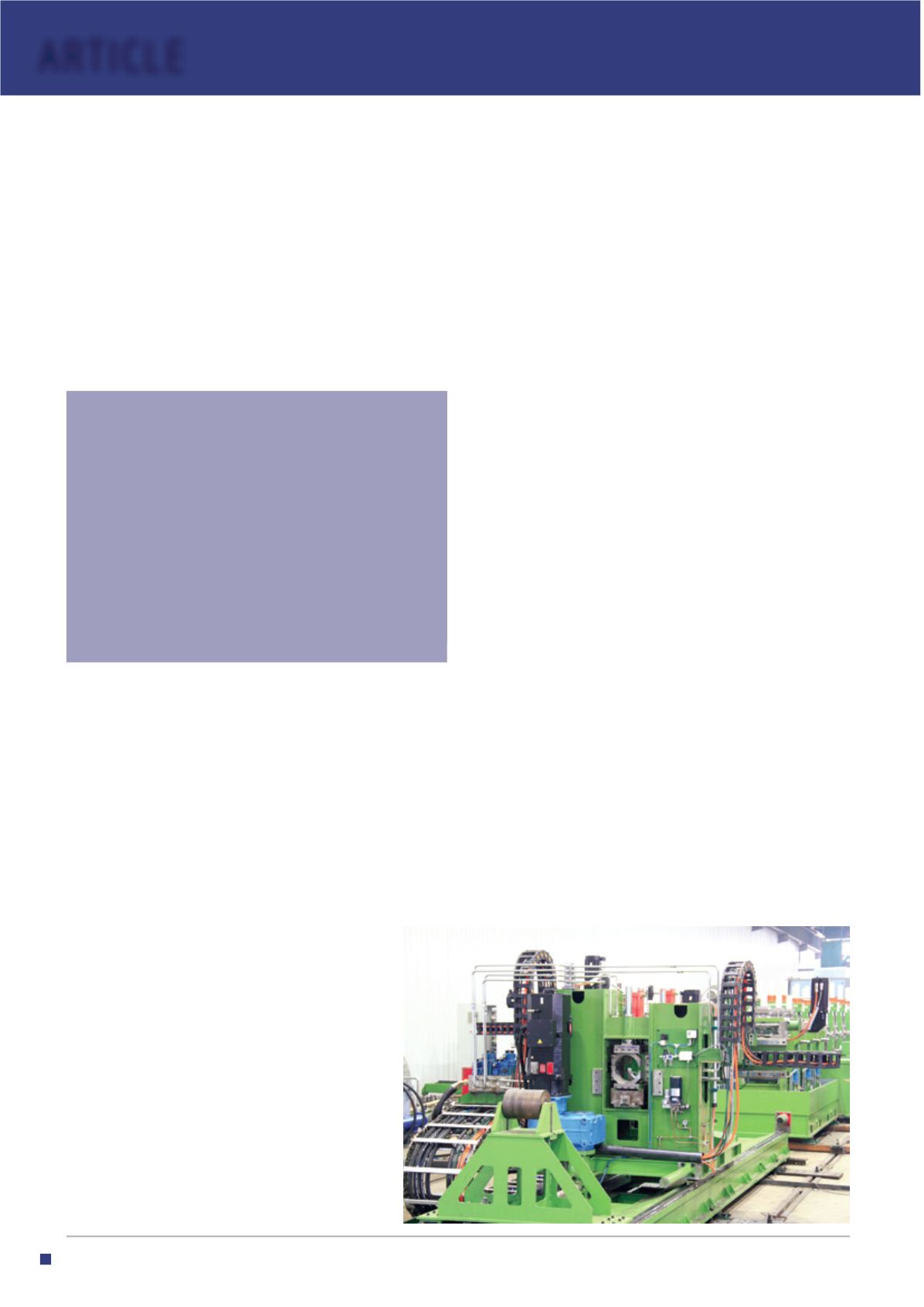

Two-blade milling saw