www.read-tpt.com

www.read-tpt.com

J

ULY

2016

77

AR T I C L E

Advanced Machine & Engineering/AMSAW

Constraints for the machine designer –

the rules of saw design

When designing a machine, engineers must consider a series

of trade-offs. For example, a circular saw blade is torsionally

very stiff, but axially or laterally to the blade plane it is very

weak. The following equation describes this rule:

D = diameter

H = thickness

E = modulus of elasticity

k = factor which includes other constants and the

clamping ratio

Rule 1

As blades increase in diameter they can

cut larger stock sizes.

However…

Larger blades have larger vibration amplitudes

and larger blades are also more expensive to

purchase and maintain.

Rule 2

As blades get thicker they become stiffer

and vibrate less.

However…

Thicker blades are heavier and more expensive because

they cost more to produce, require more horsepower,

and are more difficult to maintain and re-sharpen.

Advanced Machine & Engineering | AMSAW

– USA

2,500 Latham Street

Rockford, IL 61103, USA

Website:

www.amsaw.comHow to reduce vibration in carbide sawing

If the machine does not follow the rules above, there’s not

much that can be done by the end user to reduce vibration.

Above all else, it’s critical for long term production results that

end users purchase a stiff machine with robust design.

Additionally, we have found that increasing the feed rate to

apply more force to the cut may actually help to stabilise the

blade in the cut.

Finally, it is important to understand the difference between

stabilising and damping, making sure that the machine is

equipped with the right components for both.

Vibration is the most harmful element in carbide sawing, but

other factors, such as resonance, and stabilising and damping

components must also be considered in machine design.

My next piece will highlight the damaging effect of resonance

and what can be done to prevent it, and my final piece

will distinguish between stabilising and damping, and how

machine designers utilise components to stabilise the blade

and control vibration to design machines with the lowest cost-

per-cut for the customer.

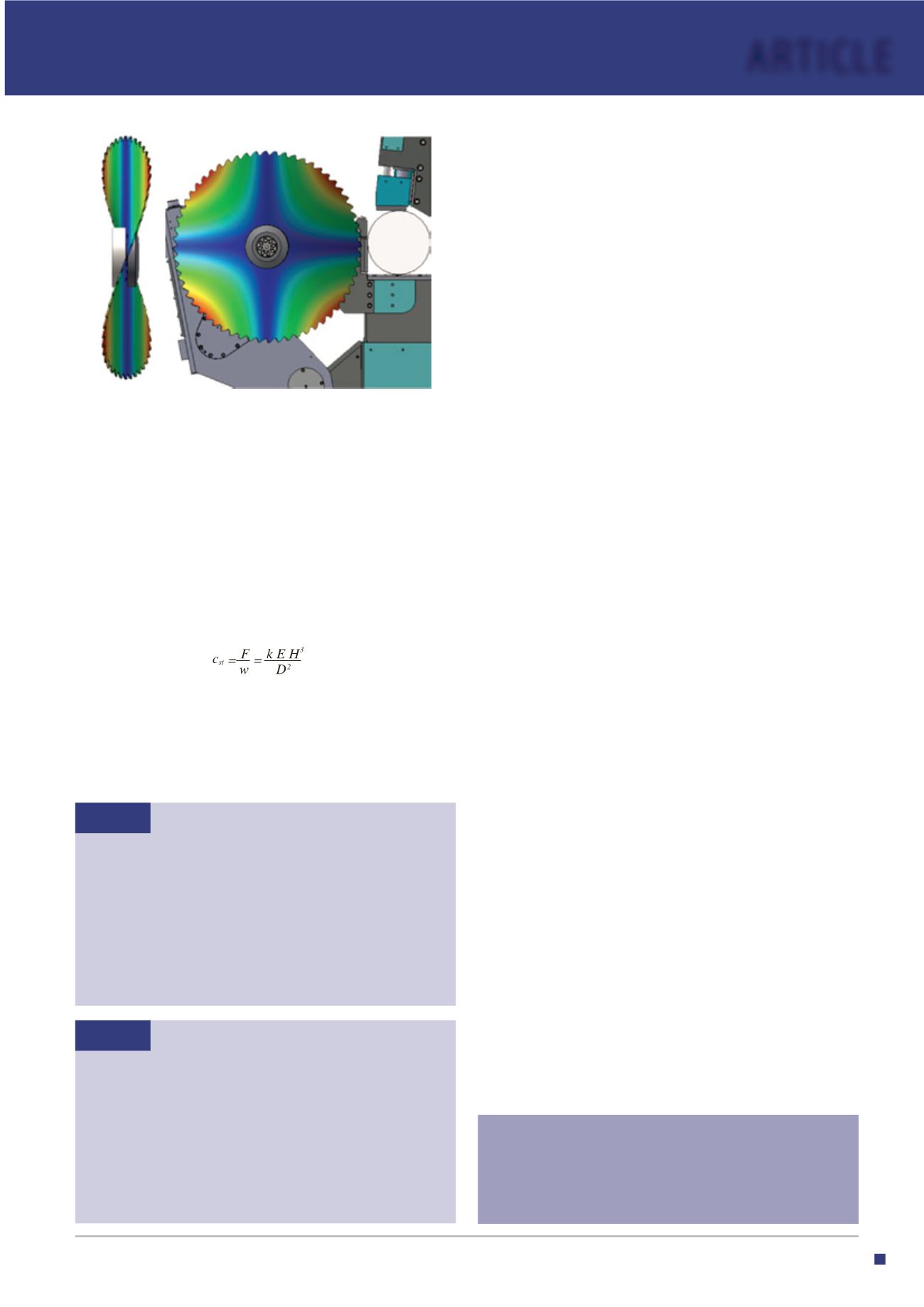

Figure 4: Vibration mode pattern of the second node diameters

typically occur at low rpm and have the most damaging effect