UPM Annual Report 2016

UPM Annual Report 2016

26

27

In brief

Strategy

Stakeholders

Governance

Accounts

Businesses

CONTENTS

furniture and joinery markets in Europe and Asia. Sawn timber is a

versatile and sustainable material, it is strong and can be reused and

recycled.

Long-term demand prospects are promising for pulp

Demand for sustainably produced chemical pulp continues to increase

globally. UPM’s four world-class pulp mills serve customers in the

growing consumer and industrial end-uses such as tissue, board and

specialty papers as well as graphic paper end-uses.

Longer term chemical pulp demand is expected to be further

underpinned by a declining supply of white recycled fibre. Supply of

white fibre will become restricted, in part due to lower graphic paper

production and in part as mixed recovered paper crowds out white

recycled fibre in the collection process.

UPMPulp offers its customers a multi-fibre product range with

direct sales to the global market. Through its own production or through

the Fibre United co-operation, UPMprovides pulp customers with the

most versatile range of northern softwood, birch, eucalyptus and semi-

chemical pulp. UPMPulp’s own sales and technical service experts are

located close to customers in the main markets and in each mill working

in close co-operation with UPM’s global research and development

network.

In July, UPM started discussions with the Government of Uruguay

regarding the development of logistics infrastructure in the country.

Railroad and road connections are a critical challenge for establishing a

large scale industrial operation in the Uruguayan inland and connecting

it to a deep sea port. UPMhas consistently increased its plantation base

in Uruguay.

Significant improvement in biofuel production efficiency

UPMhas been producing UPMBioVerno renewable drop-in diesel

fromwood-based residues since early 2015. UPMBioVerno is a unique,

competitive and sustainable alternative to fossil fuels or first-generation

biofuels, and is well positioned among the few existing biofuel

alternatives available on the market. UPMBioVerno significantly

reduces greenhouse gas and tail-pipe emissions. Demand is predicted

to be strong for sustainable, high-quality advanced biofuels.

The UPMLappeenranta Biorefinery is the first of its kind in the

world. Production is based on a hydrotreatment process developed

by UPM, and the capacity is approximately 120 million litres, which

is 100,000 tonnes.

In terms of profitability, UPMBiofuels reached the break-even point

already in the fourth quarter of 2015. In 2016, the production efficiency

improved significantly and production reached a record level. Strong

biofuels markets, in particular towards the end of 2016, also contributed

positively to the sales and profitability of UPMBioVerno compared

to 2015.

To expand target markets, field tests progressed with dedicated

fleets, public transportation and shipping. The field tests focused on fuel

functionality, emissions and fuel consumption compared to fossil diesel.

UPMBioVerno diesel tests in both marine transportation and public

buses provided good results —UPM’s renewable diesel is well-suited

for both end uses even as 100% pure renewable diesel, and functions

as well as the best quality fossil-based diesels.

The UPMLappeenranta Biorefinery is the first significant invest

ment in a new and innovative production facility. Having proven that

the technology and business case work, UPMhas started evaluating

future growth opportunities. The planning includes new alternatives

in sustainable liquid feedstocks, newmarkets and customer segments

as well as applications and product development. UPMwill continue

developing new process technologies using solid wood biomass.

Efficient use of renewable materials and energy

UPMhas leading competencies both in plantation and industrial

operations as well as in environmental and social responsibility.

UPM’s modern pulp mills have certified environmental manage

ment systems in place and the production technology enables efficient

use of rawmaterials, chemicals, energy and water. In wood sourcing,

UPMmeets the highest sustainability demands in the industry.

UPMBioVerno is a sustainable alternative that helps mitigate climate

change. Demand for advanced biofuels is being driven by stricter

environmental standards and sustainability.

UPM brings life to the whole community. It plays an active role in

the local community as an employer fostering safety and healthy living,

and as a business partner. Communities and businesses have grown

around UPMpulp and timber operations over the years.

Responsibility offer both competitive advantages and growth

opportunities for UPMBiorefining.

•

Capital intensive process industry

•

Engaged high performing people

•

Responsible raw material sourcing

•

Integration to internal raw-material

•

Intellectual property rights

•

Community engagement

CAPITALS

UPM BIOFUELS

VALUE CREATED

Advanced renewable diesel and naphtha

Competitive and sustainable non-food feedstock

Infrastructure synergies

Sustainability leader in biofuel solutions in Europe

Intellectual property rights

•

Oil majors

•

Distributors and retailers

•

Dedicated heavy-duty fleets

•

Marine fleets

CUSTOMERS

•

Employment

•

Work safety

•

Community wellbeing

•

Low-emission

transportation fuels

•

Renewable energy

•

Sustainable products

•

ROCE

•

Growth

•

Best available technology

OUTCOMES

SOCIAL

IMPACT

ECONOMIC

IMPACT

ENVIRONMENTAL

IMPACT

CLEANER PUBLIC TRANSPORT

UPM’s wood-based UPM BioVerno biofuel has

been proven to reduce carbon dioxide and particle

emissions in both urban and maritime transport.

UPM has been testing UPM BioVerno diesel fuel

in Helsinki region buses in collaboration with the

Helsinki Region Transport (HSL) for a year. Traffic

is the main source of emissions in cities affecting

air quality.

According to the test results, using UPM BioVerno

in the current bus fleet instead of fossil diesel would

significantly reduce emissions resulting from public

transport. By using wood-based fuel, air quality in

the Helsinki region could be improved quickly. The

tailpipe emissions of UPM BioVerno, such as nitrogen

oxides and particulate matter, were significantly

lower than those of the commercial grade fossil

diesel in laboratory testing.

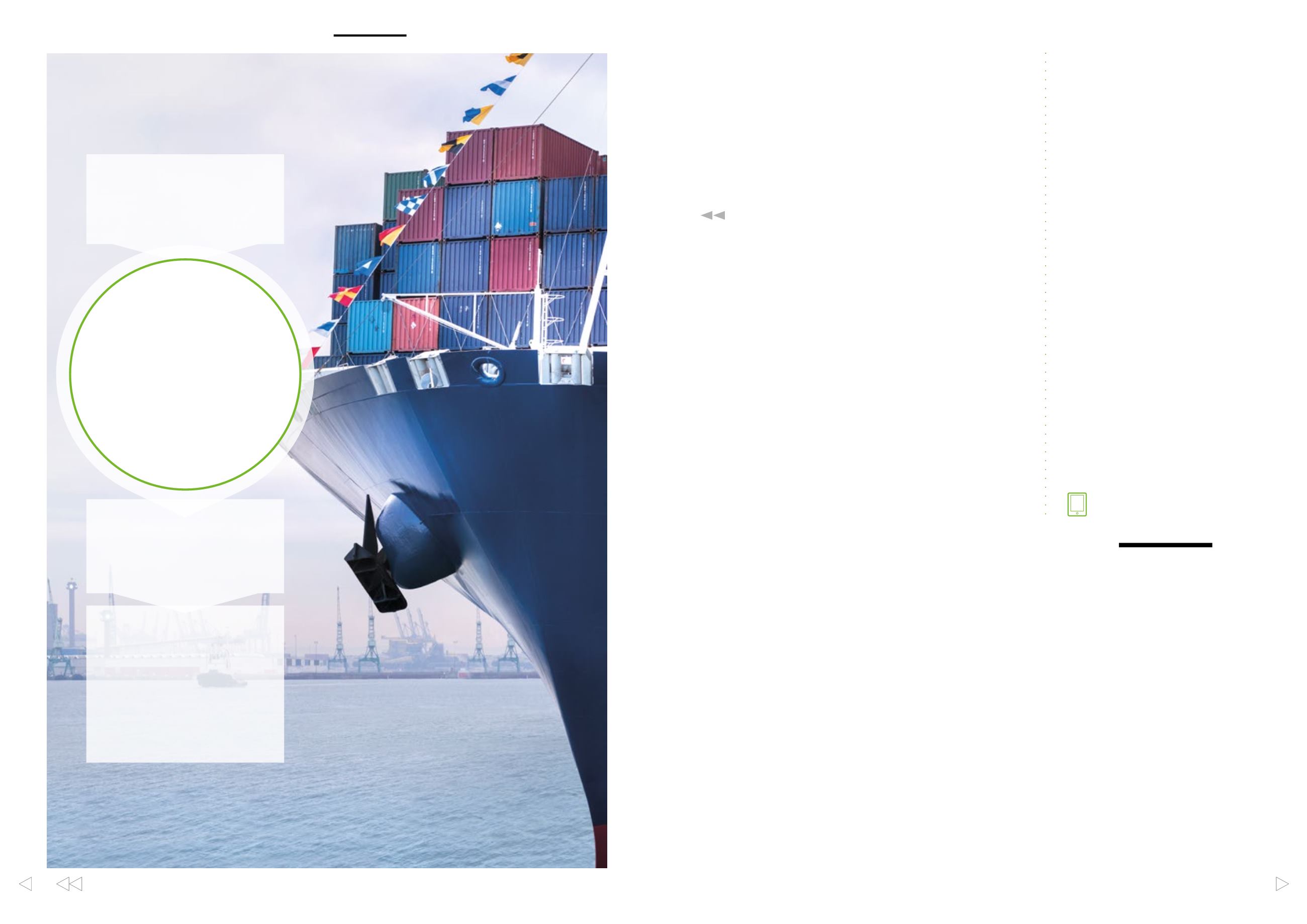

Maritime transport is looking for new ways to

reduce carbon dioxide and sulphur emissions.

In the beginning of 2017, the Marine Environment

Protection Committee of the International Maritime

Organization (IMO) agreed that the sulphur content

limit of ships’ fuel will be lowered to 0.5% starting

from 2020 in all maritime transport.

Increasing the use of biofuels in ships is a cost-

effective alternative. In 2016, UPM BioVerno was

tested for the first time in a marine vessel in the diesel

engine of a dredger. Biofuels offer ship operators

a way to reduce ships’ carbon dioxide emissions

by 80-90% and eliminate sulphur emissions.

Read more: www.upmbiofuels.com