www.read-tpt.com

www.read-tpt.com

70

J

ULY

2016

T UBE M I L L S & R OL L FORM I NG L I NE S

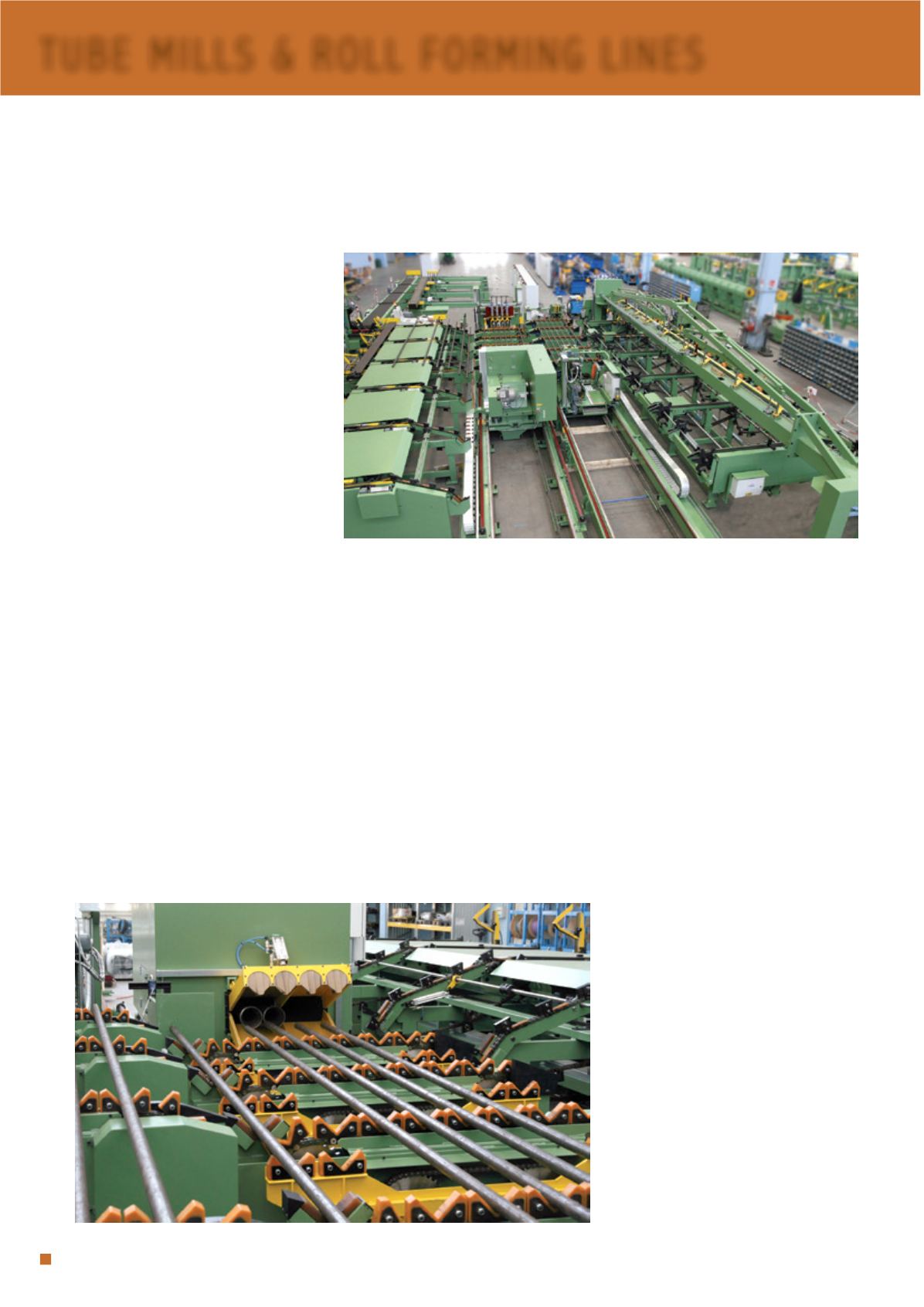

Mair Research supplies new finishing line

for automotive tubes in Mexico

MAIR Research has recently supplied an

integrated finishing line for processing

precision tubes for an important

Mexican supplier of automotive tubing.

In this project the tubes are 88.9mm in

diameter and 12m in length.

The line is placed at the direct exit of

the new tube mill and designed to allow

the maximum mill productivity ensuring

continuous processing and collecting of

the finished tubes in strapped bundles

ready for delivery to the end user.

The layout has been custom designed

together with the customer to optimise

the available floospace.

Since all operations are performed

automatically only two operators with

supervisory tasks are sufficient to

conduct the line.

The line consists of the following

equipment:

• Driven rollway interfaced with the

tube mill and equipped with cradle for

the automatic collection of reject tubes.

• Tube sampling station. Tubes that

require sample cut-off are automatically

extracted from the production flow and

positioned to an upper cold saw for

cutting of sample piece (generally max

300mm length). The remaining (nominal

length) tube is automatically reinserted

in the production flow.

• Chamfering machine. Both ends

of round tubes are chamfered (facing,

ID and OD bevel). The machine

is equipped with a quick spindle

replacement allowing the user to reduce

the downtimes upon size changeover.

Upon changing tube length the mobile

part of the equipment (conveyors and

mobile head) will relocate automatically

to the new position.

• Swarf removal station. Suitable

to flushout the loose inner bead of

two tubes at a time in two stages.

Pressurised emulsion jets act in the first

stage and compressed air in the second

stage.

The bead is ejected to a swarf

chopper which, by rotating knives, will

chop the long swarf into short pieces

conveniently collected inside a bin.

• Packaging machine. The tubes are

automatically packed into hexagonal or

square/rectangular bundles and then

strapped. The weighing station will tilt

the bundles to remove any residual

emulsion and weigh the bundles, which

will be ready on the storage chains to be

picked up by an overhead crane.

A printer produces a customised anti-

tear label including the company logo,

bar code, weight and other data as

required.

The line is high-productive and

designed to cope with the mill speed,

and may also handle square and

rectangular tubes, which will be sent

directly to the packaging machine and

packed into final products.

Particular attention is given to tube

handling as all parts that may come in

contact with the tube are plastic coated

in order to avoid denting and scratching.

Mair Research specialises in the

design, manufacture and supply of

finishing lines in general (automotive,

OCTG, drawn, other) having delivered

to important world producers in the field

of ERW and seamless tubes.

All Mair Research equipment is fully

designed, manufactured and assembled

at the company’s facilities in Italy.

It undergoes strict pre-shipment tests

usually conducted in the presence of the

customer.

Pre-shipment tests have proven to

be beneficial, allowing the equipment to

be optimised in-house, reducing on-site

start-up and commissioning works.

Mair Research SpA

– Italy

Fax: +39 0445 634 409

Email:

salesdept@mair-research.comWebsite:

www.mair-research.com