Technical article

March 2015

88

www.read-eurowire.comWhere:

t

f

is time to failure (lifetime)

t

p

is proof test time

σ

p

is proof test stress

σ

a

is applied stress

F is failure probability

N

p

is the proof test break rate

L is the length under tension

m

d

is the Weibull m parameter from

dynamic fatigue

n is the stress corrosion parameter

The expression is complex, but we can

make a few observations.

Figure 1

shows that the greater the applied

stress, the greater the failure probability.

Thus, the failure probability term in the

equation, F, is directly related to the

applied stress term, σ

a

. The traditional rule

of thumb that has been used to derive 20

per cent of the proof stress as a long-term

maximum allowable load assumes these

two variables are independent, which is

not consistent with

Figure 1

. Hundreds of

kilometres of fibre must be tested to fully

understand the relationship between the

failure rate and the applied stress.

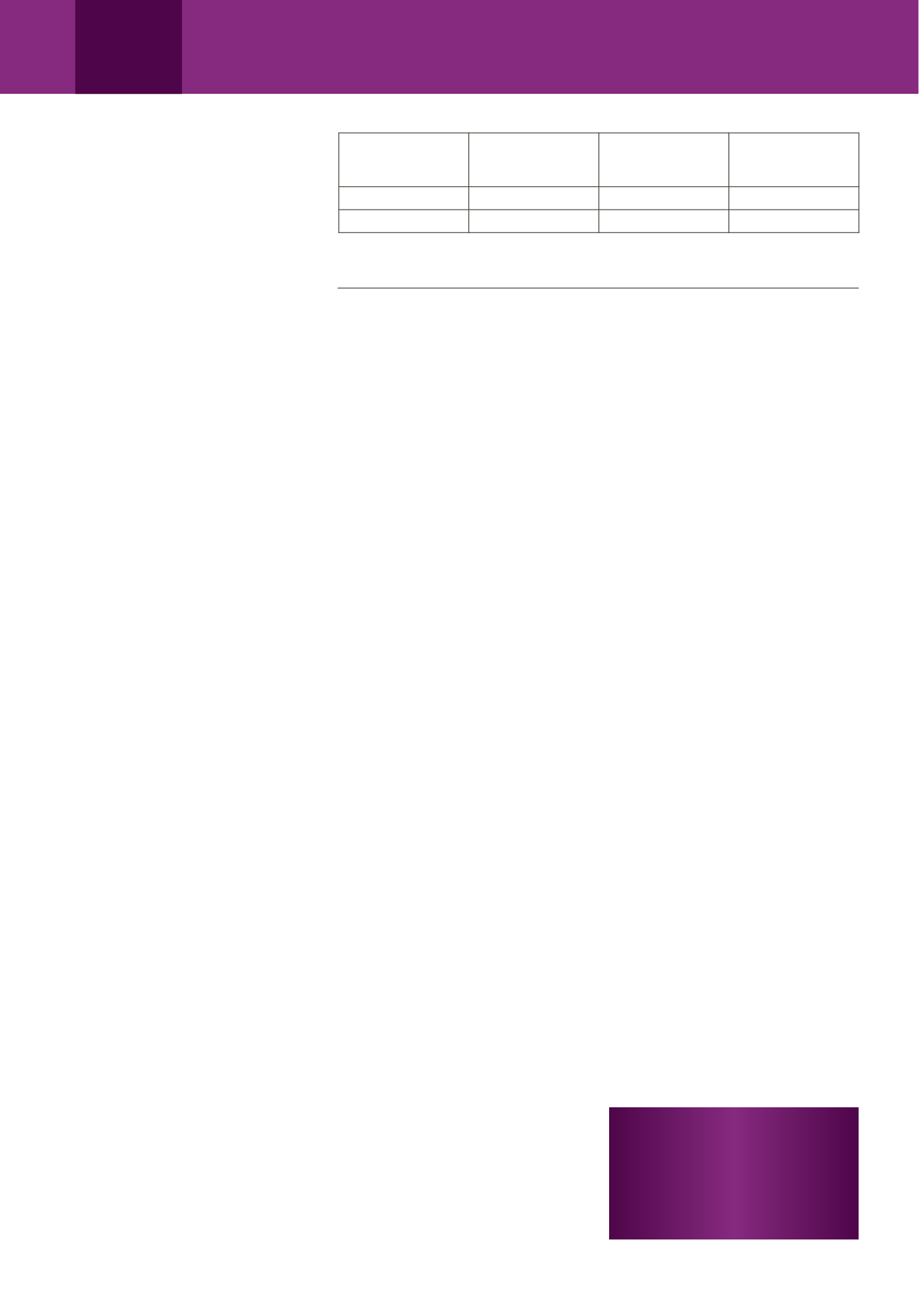

Table 1

gives the results comparing three

scenarios. The first is 0.69 GPa proof-tested

fibre with a long-term load of 20 per cent

of the proof-test load. Generating the data

we used following values substituted into

Equation 1

:

n

d

=20

m

d

= 2.5

t

p

= 0.05 seconds

N

p

= 1 break every 250km

The table shows that an optical fibre

meeting the conservative criteria above

would exhibit reasonable mechanical

performance for the 0.69 GPa at 20 per

cent of the proof test level. The second

case shows that the same fibre was

maintained at 40 per cent of the proof test

level. In this case, the 1ppm failure rate

would be reached in less than a year. The

third case is 1.38 GPa proof-tested fibre

with a long-term load of 20 per cent of the

proof test level.

For this set of conditions, 1ppm failure

probability is met in less than six years.

Note that data in

Table 1

is representative

of fibre in a non-aggressive environment.

Terms such as zero stress ageing, macro

bends, abrasion and other factors can

greatly reduce the fibre lifetime.

5 Discussion

Fibre lifetime is the sum of the intrinsic

and extrinsic failure probability. This paper

focuses on long lengths of fibre under

axial load in a regime where failure is

dominated by extrinsic failures. The results

shown in

Table 1

highlight the error in the

common requirement for optical cables,

which holds that the long-term load on

the optical fibres is simply 20 per cent of

the proof-test level. If the fibre break rate

was the same for the 0.69 GPa and 1.38

GPa proof tested fibre, then both fibres

would have the same 1ppm life-time.

We know this is not the case from the

data of

Figure 1

. When this knowledge is

included in the analysis, the results change

dramatically.

Typically, long-term reliability expectation

for optical cables is that the fibre failure

probability should be less than 1ppm in

30 years. Using this criterion, the example

given in

Table 1

can be simplified as

follows:

• 0.69 GPa fibre at 20 per cent long-term

load will provide reliable performance

• 0.69 GPa fibre at 40 per cent long-term

load

will

not

provide

reliable

performance

• 1.38 GPa fibre at 20 per cent long-term

load

will

not

provide

reliable

performance

Though it is apparent that proof-testing

at higher levels greatly improves the

performance of the cables, the value

commonly used in cabling standards – 20

per cent of the proof test level – can lead

to false expectations about the long-term

reliability of the optical cables.

6 Recommendations

The information described in this

document indicates that, though 20 per

cent of the proof-test load for a long-term

load on optical fibre may be a reasonable

criterion for optical fibre proof-tested at

0.69 GPa or less, it may produce optimistic

estimations for optical fibre proof-tested at

higher levels.

Currently, most major optical fibre

standards, including those in ITU-T,

IEC, and TIA, require the fibre to be

proof-tested at 0.69 GPa. Cable standards

in IEC, ICEA and IEEE should align with

this criterion. It is thus recommended that

the documents be modified to simply

require maximum long-term load of

0.14 GPa (20 kpsi) on the cabled optical

fibre after deployment, regardless of the

proof-test level. A note could be added to

the requirement stating that when optical

fibre with proof-test levels higher than

0.69 GPa is deployed, higher strains on

the optical fibre will affect reliability and

should be agreed to by the cable supplier

and end user, and that more precise fibre

reliability models should be considered.

7 Conclusions

This paper has shown that modern cable

designs are pushing the design limits

for allowable long-term strain in optical

cables. Under these new boundary

conditions, the old rule of thumb allowing

up to 20 per cent of the proof-test level

as a long-term strain may no longer be

appropriate. A new recommendation

requiring the long-term load be limited

to 0.14 GPa is proposed as an alternative

criterion. This new criterion should be

included in upcoming revisions of fibre

cable

standards.

Particularly

critical

designs are high-strain cable types such as

drop cable, and overhead cables including

OPGW and ADSS cables.

n

8 Acknowledgments

Special thanks to Peter Hasløv (OFS),

Hiroshi Nakamura (Furukawa) and Peter

Pondillo (Corning) for their helpful discus-

sions on fibre lifetime.

9 References

[1]

Steven R Schmid, et. al, ‘Development and

Characterisation of a Superior Class of Micro

bend Resistant Coatings for Today’s Networks’,

Proceedings of the 58

th

IWCS, (2009), 72-78

[2]

Glaesemann, G S, and Gulati, S T, ‘Design

Methodology for the mechanical reliability of

optical fibre’, Optical Engineering, June 1991,

Vol 30 No 6, 709-715

[3]

Castilone, Glaesemann G S, and Hanson,

T, NFOEC-2000, 1-9 (August 2000)

[4]

IEC TR 62048 Power Law Reliability

Paper courtesy of the 62

nd

International Wire

and Cable Symposium, North Carolina, USA,

10

th

to 13

th

November 2013.

Failure probability

of 1km of optical

fibre

0.069 GPa proof

tested fibre 20 per

cent long-term load

0.069 GPa proof

tested fibre 40 per

cent long-term load

1.38 GPa proof

tested fibre 20 per

cent long-term load

1.0ppm per km 1,600 years

0.0 years

530 years*

1.0ppm per 100km 16 years

0.0 years

5.3 years*

* The failure rate varies greatly, with the change in proof-test going from0.69 GPa to 1.38 GPa

▲

▲

Table 1

:

Comparison of failure probabilities (1ppm lifetime)

OFS

2000 Northeast Expressway

Norcross, Georgia

USA

Tel

: +1 508 637 1114

:

dmazzarese@ofsoptics.comWebsite

:

www.ofsoptics.com